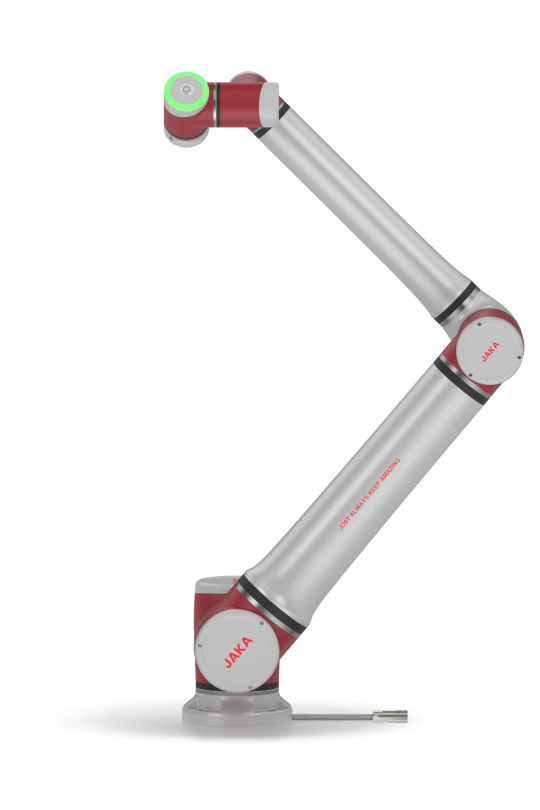

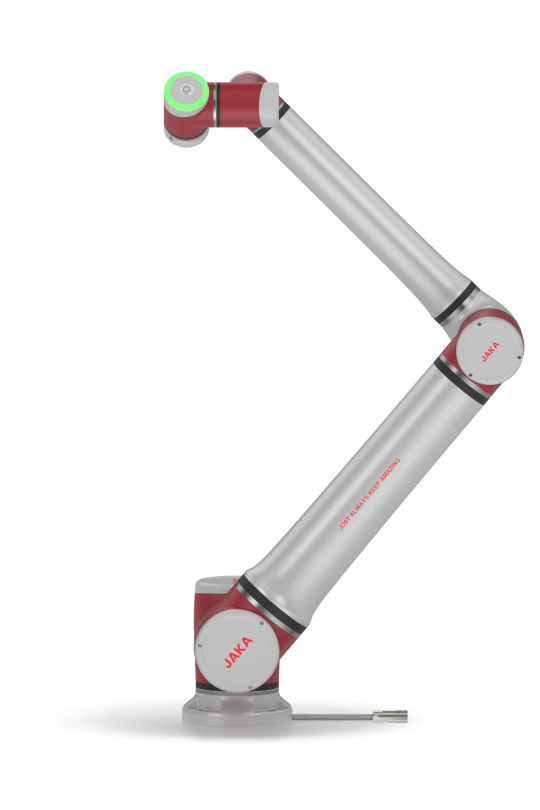

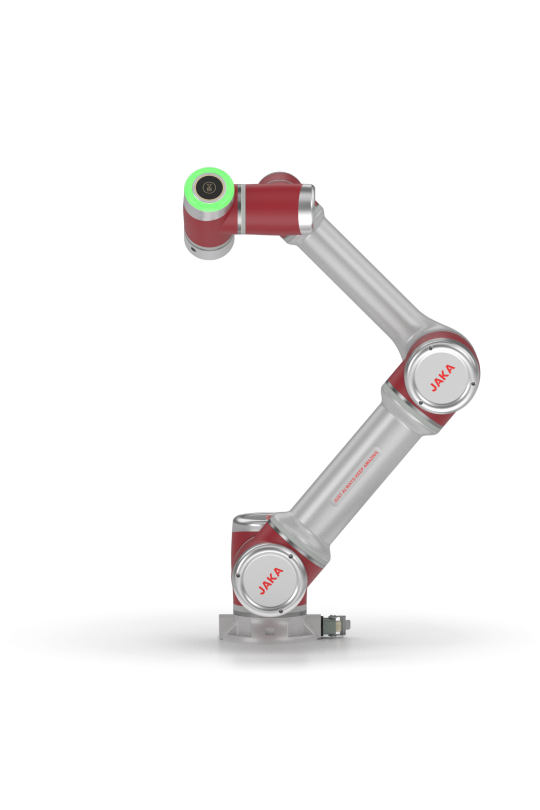

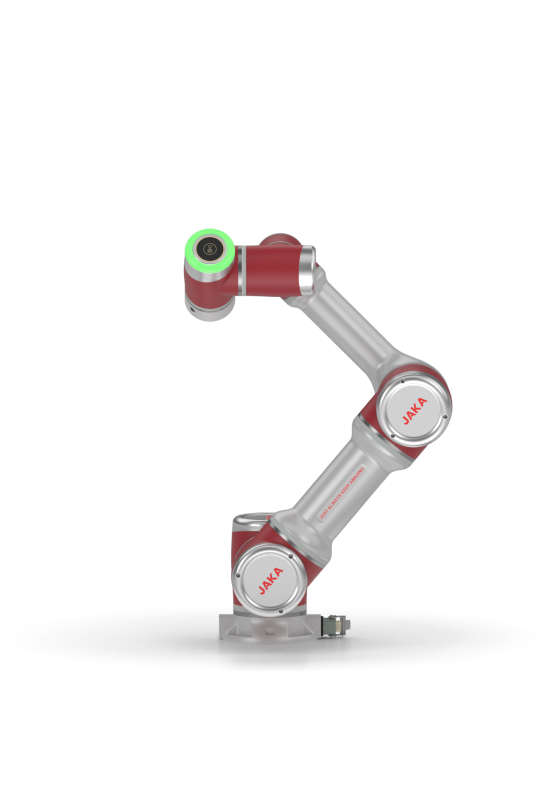

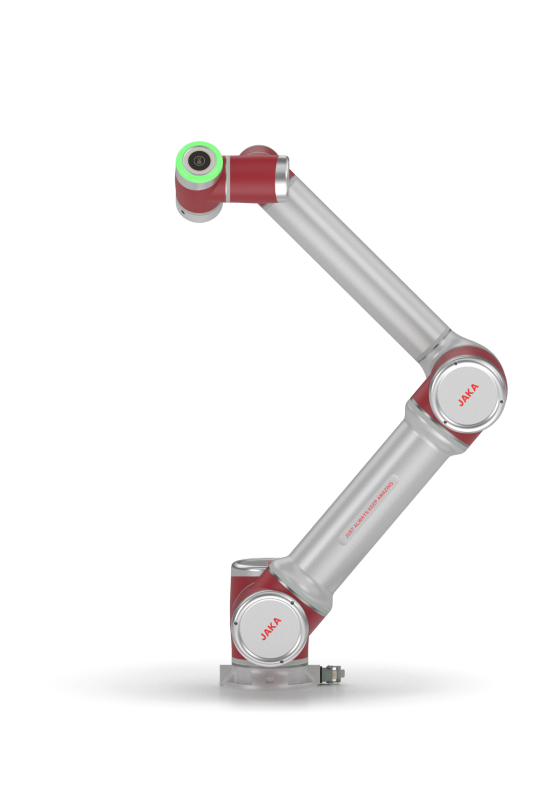

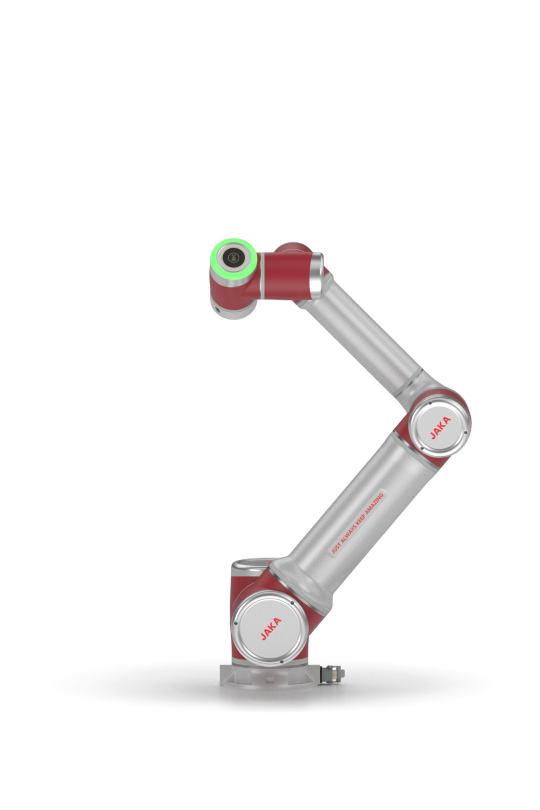

JAKA Zu20

Payload: 20 kg, Weight: 68 kg, Reach: 1780 mm

Designed for heavy payload and wide reach applications with comparatively high accuracy. IP65 protection suitable for tasks in robust environment such as loading and unloading, palletizing, and packaging of heavy and large-sized workpieces.

Contact UsDesigned for heavy payload and wide reach applications with comparatively high accuracy. IP65 protection suitable for tasks in robust environment such as loading and unloading, palletizing, and packaging of heavy and large-sized workpieces.

Product Parameters

Maximum payload

20 kg (44.1 lb)

Weight (incl. cables)

68 kg (149.9 lb)

Accuracy

±0.05 mm (±0.00120 in)

Programming

Graphic programming, drag & teach, SRCI, offline programming

Programming interface

Any graphical device (PC, tablet, or smartphone)

Nominal power consumption

750W

Tool I/O Interfaces

2 digital inputs/

2 digital outputs/

2 analog inputs

Base Diameter

246 mm (9.685 in)

I/O Interfaces

16 digital inputs, 16 digital outputs, 2 analog inputs or outputs

Communication Protocols

TCP/IP,Modbus TCP,Modbus RTU, Profinet, Ethemet/lP

Power Supply

100-240VAC,50-60Hz

Size

410×307×235 (mm) (W×H×D)

Series Products

Application Scenario

Loading and Unloading

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Packing

Can spray complex curves with precision control to save paint .

High-precision repeatability ensures product quality, reducing operational costs and minimizing reworked parts and scrapped parts.

Replaces manual labor, reduces management costs, effectively improves production rate

Palletizing

Achieves automated palletizing, improves production efficiency, and enhances the working environment for operators.

A single robot can manage multiple production lines, significantly reducing costs

Compact structure, small footprint, high integration, and lightweight, effectively solving manual palletizing tasks on-site for customers.