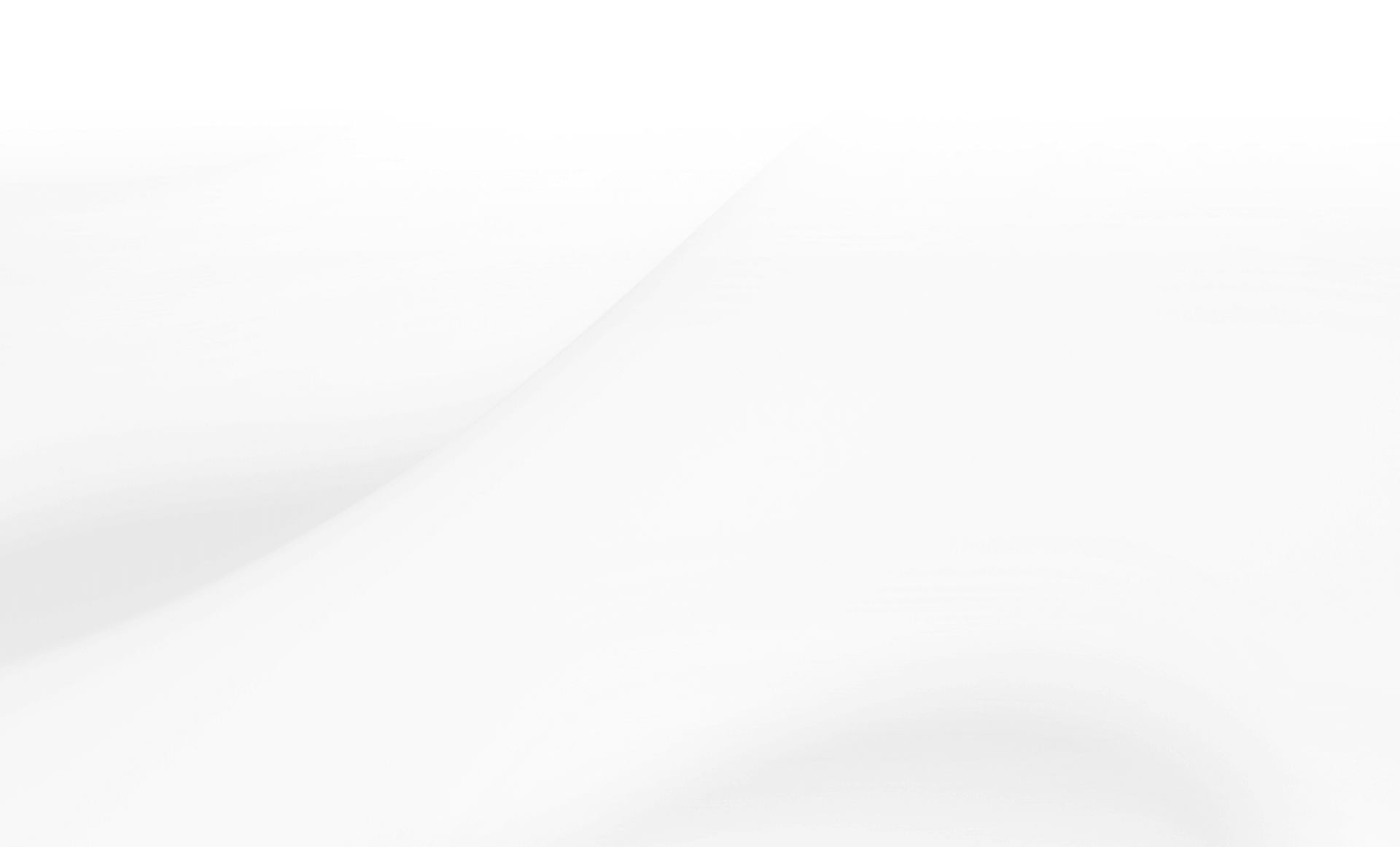

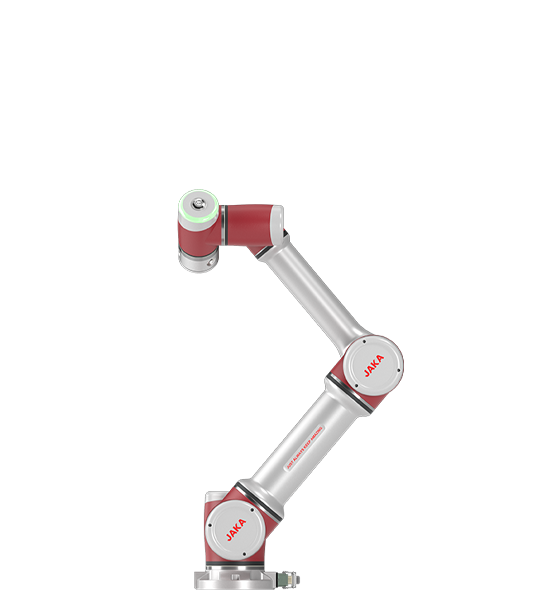

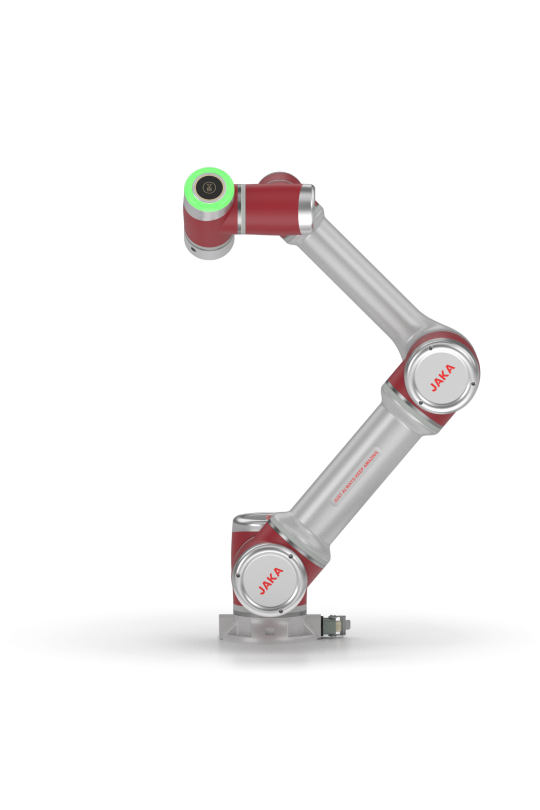

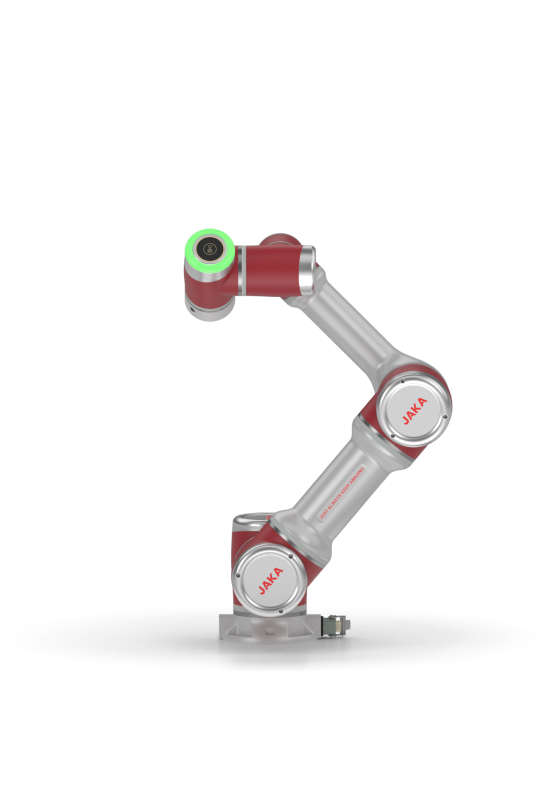

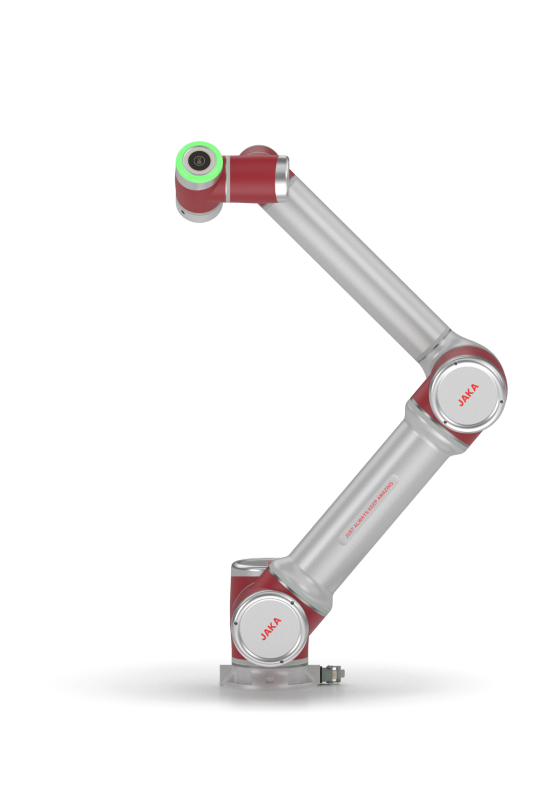

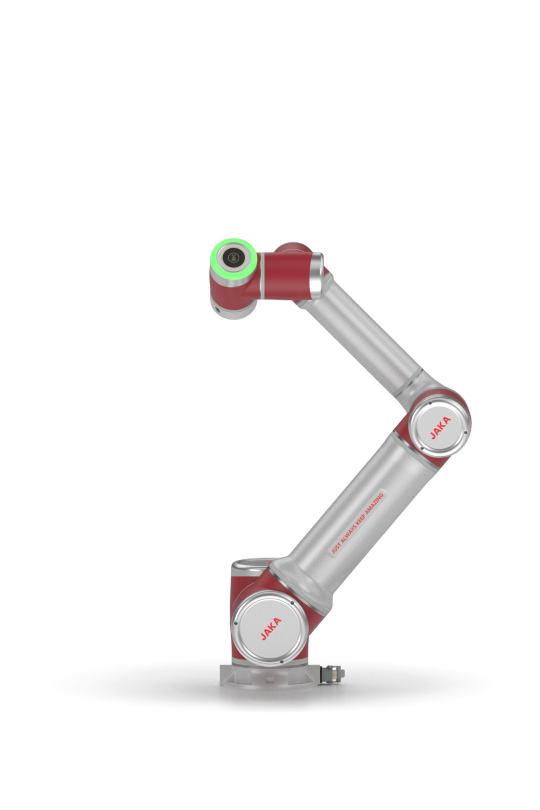

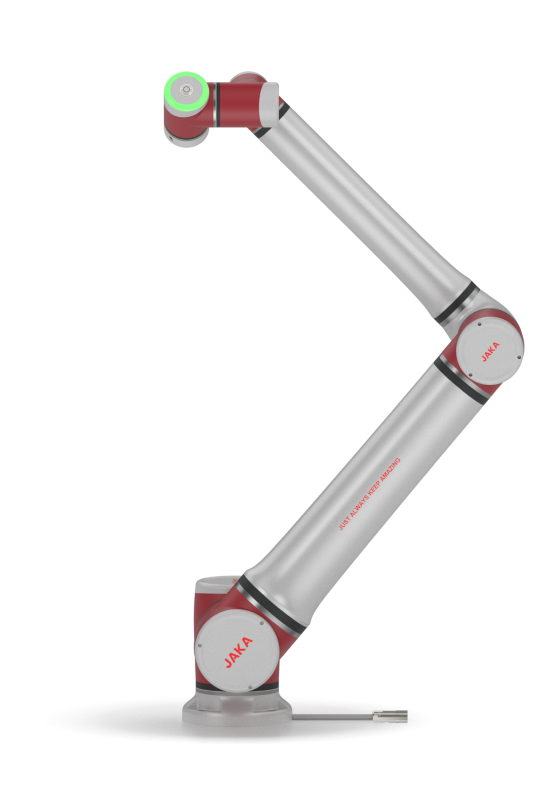

JAKA S12

Payload: 12 kg, Weight: 41 kg, Reach: 1327 mm

Equipped with a built-in force sensor, allowing the robot to sense forces from multiple directions with exceptional adaptability, rapid response, and high precision. Ready to use immediately, without the need for external sensor integration. Singularity protection ensures safe, smooth, and predictable movement, making the JAKA S series the perfect solution for enhanced drag teaching and all kind of forced controlled applications.

Contact UsEquipped with a built-in force sensor, allowing the robot to sense forces from multiple directions with exceptional adaptability, rapid response, and high precision. Ready to use immediately, without the need for external sensor integration. Singularity protection ensures safe, smooth, and predictable movement, making the JAKA S series the perfect solution for enhanced drag teaching and all kind of forced controlled applications.

Product Features

Easy Deployment

Instant access to force control for seamless setup and quick integration

01

Enhanced Durability

With an IP65 rating, JAKA S offers superior protection against dust and water, ensuring long-lasting performance

02

Precision Handling

Integrated force control enables effortless and precise operation, ensuring consistent results

03

Easy Deployment

Instant access to force control for seamless setup and quick integration

Enhanced Durability

With an IP65 rating, JAKA S offers superior protection against dust and water, ensuring long-lasting performance

Precision Handling

Integrated force control enables effortless and precise operation, ensuring consistent results

Product Parameters

Maximum payload

12 kg (26.5 lb)

Accuracy

+0.03 mm (±0.00118 in)

Programming

Graphic programming, drag & teach, SRCI, offline programming

Programming interface

Any graphical device (PC, tablet, or smartphone)

Nominal power consumption

500w

Tool I/O Interfaces

2 digital inputs/ 2 digital outputs/ 2 analog inputs

Base Diameter

188 mm (7.402 in)

Force/torque sensor

Force/Torque, x-y-z

Force/torque range

400N/48Nm

Maximum overload

3000N/ 300Nm

I/O Interfaces

16 digital inputs, 16 digital outputs, 2 analog inputs or outputs

Communication Protocols

TCP/IP, Modbus TCP, Modbus RTU, Profinet, Ethernet/IP

Power Supply

100-240VAC, 50-60Hz

Size

410×307×235 (mm) (W×H×D)

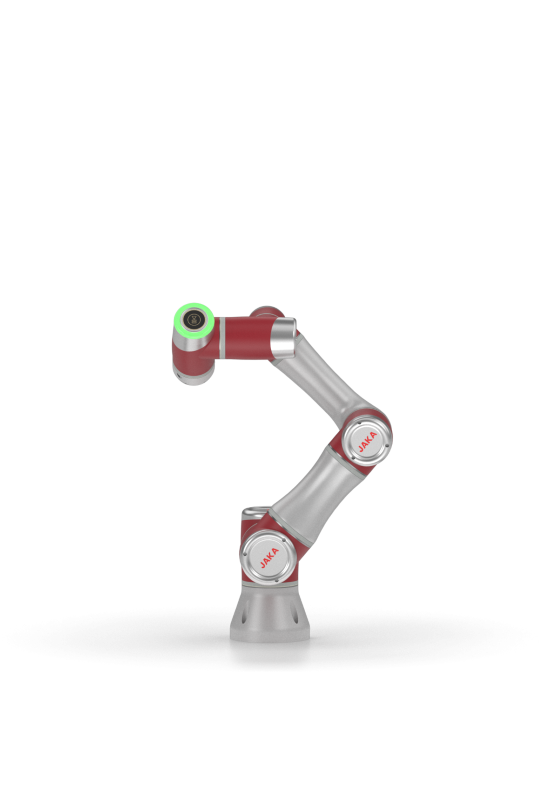

Series Products

Application Scenario

Gluing

Convenient and easy to use, easily movable within the working area, greatly enhancing flexibility and user experience.

Replaces manual dispensing, achieving mechanized production. Improves the appearance of dispensing, accurately controls flow, saves glue, reduces labor costs.

Screwdriving

The operation of the JAKA‘s robots is quick and responsive.

High efficiency, stability, and quality enable highly intelligent, automated screwdriving operations.

Torque adjustment range can be configured according to screwdriving product requirements, with each axis adjustable independently.

Flexible Assembly

High-precision adaptive assembly effectively prevents workpiece loss and increases productivity.

Lightweight design enables quick deployment on the production line.

Supports small-batch, multi-variety production.

Flexible Grasping

Supports small-batch, multi-variety production.

High-precision adaptive assembly effectively prevents workpiece loss and increases productivity.

Lightweight design enables quick deployment on the production line.

Polishing and Grinding

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Welding

Debugging mode: Supports empty program run without arcing for easy verification of teaching points.

Versatile: Compatible with major domestic and international welding machine brands.

Force control drag: Supports payloads from 3-18kg with force control sensors for smooth operation and handy point teaching.

Easy configuration: A new settings interface facilitates communication setup between the robot and welding machine. Safety interlock: Alarm signals between the robot and welding machine ensure reliable operation.

Manual control: Supports manual arc start/stop, gas feed/discontinuation, and step/continuous wire feeding.

Load and go: Simply load the arc welding process package via the app.