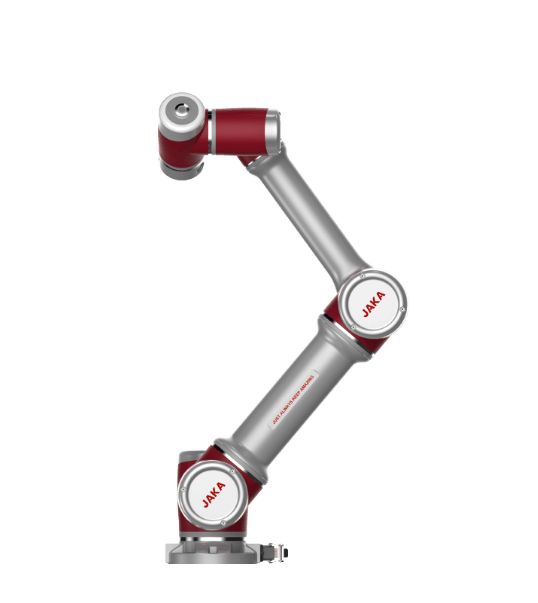

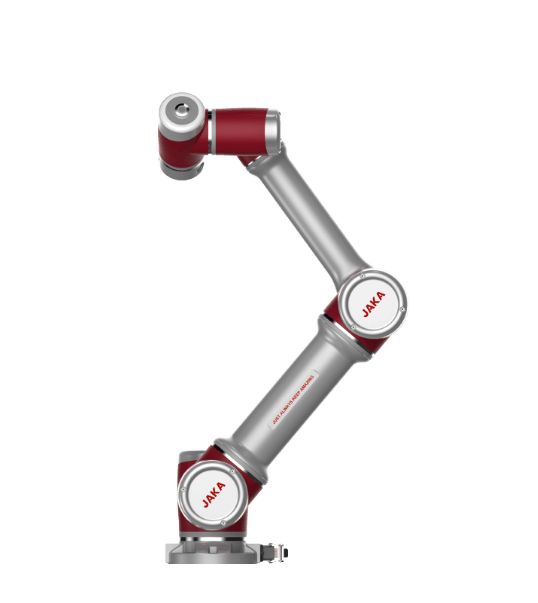

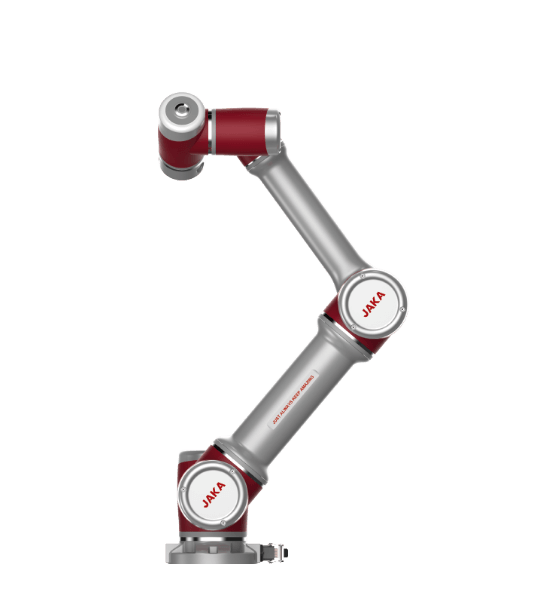

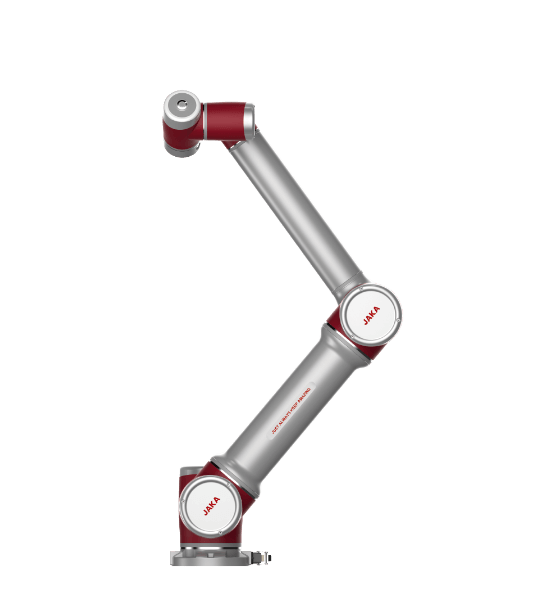

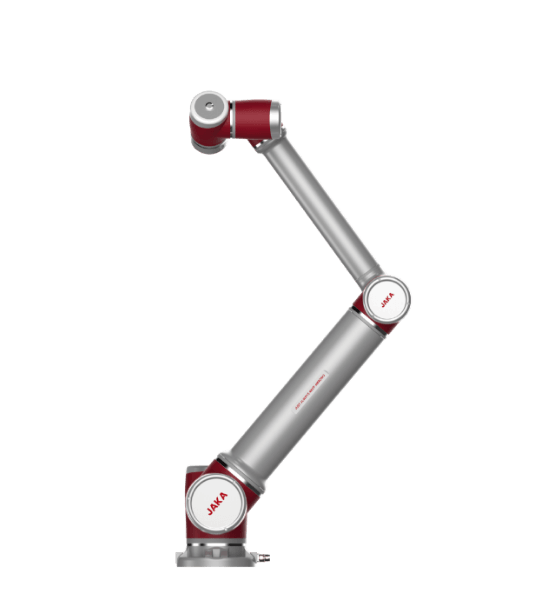

JAKA Pro5

Payload: 5 kg, Weight: 23.5 kg, Reach: 954 mm

Equipped with IP68 protection, built to thrive in the most demanding industrial environments, ideal for applications requiring resistance to dust, small particulates, and liquids such as water and oil. Capable of operating non-stop for years in harsh conditions, temperatures ranging from -10°C to 50°C.

Contact UsEquipped with IP68 protection, built to thrive in the most demanding industrial environments, ideal for applications requiring resistance to dust, small particulates, and liquids such as water and oil. Capable of operating non-stop for years in harsh conditions, temperatures ranging from -10°C to 50°C.

Product Features

Maximum Durability

With IP68 protection, JAKA Pro is built to withstand dust, oil, and water, ensuring top-tier durability in tough environments

01

Consistent Precision

Achieve 0.02 mm repeatability for reliable, 24/7 unsupervised operation, delivering precision around the clock.

02

Efficient Integration

Quick to deploy, easy to integrate, and simple to reprogram, JAKA Pro makes automation setup smooth and hassle-free.

03

Maximum Durability

With IP68 protection, JAKA Pro is built to withstand dust, oil, and water, ensuring top-tier durability in tough environments

Consistent Precision

Achieve 0.02 mm repeatability for reliable, 24/7 unsupervised operation, delivering precision around the clock.

Efficient Integration

Quick to deploy, easy to integrate, and simple to reprogram, JAKA Pro makes automation setup smooth and hassle-free.

Product Parameters

Maximum payload

5 kg (11 lb)

Weight (incl. cables)

23 kg (50.71 lb)

Accuracy

+0.02 mm (±0.00079 in)

Programming

Graphic programming, drag & teach, SRCI, offline programming

Programming interface

Any graphical device (PC, tablet, or smartphone)

Nominal power consumption

350W

Tool I/O Interfaces

2 digital inputs/

2 digital outputs/

2 analog inputs

Base Diameter

158 mm (6.220 in)

I/O Interfaces

16 digital inputs, 16 digital outputs, 2 analog inputs or outputs

Communication Protocols

TCP/IP,Modbus TCP,Modbus RTU, Profinet, Ethemet/lP

Power Supply

100-240VAC,50-60Hz

Size

410×307×235 (mm) (W×H×D)

Weight

15.4 kg (33.95 lb)

Series Products

Application Scenario

Welding

Easy configuration: A new settings interface facilitates communication setup between the robot and welding machine. Safety interlock: Alarm signals between the robot and welding machine ensure reliable operation.

Load and go: Simply load the arc welding process package via the app.

Manual control: Supports manual arc start/stop, gas feed/discontinuation, and step/continuous wire feeding.

Versatile: Compatible with major domestic and international welding machine brands.

Debugging mode: Supports empty program run without arcing for easy verification of teaching points.

Force control drag: Supports payloads from 3-18kg with force control sensors for smooth operation and handy point teaching.

Polishing and Grinding

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

Loading and Unloading

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Handling

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.