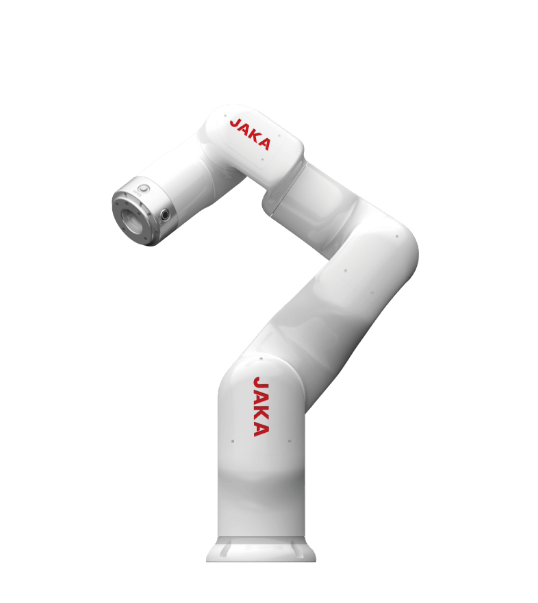

JAKA Mini 2

Payload: 2 kg, Weight: 9.9 kg, Reach: 580 mm

Mini 2 is the next evolution in compact collaborative robotics, offering double the payload and four times the acceleration of its predecessor – all while maintaining the same small footprint, intuitive setup, and affordable price.

Designed for SMEs and beyond, it brings faster cycle times, broader use cases, and seamless integration with the entire JAKA ecosystem.

From inspection and 3D vision tasks to high-speed handling in space-constrained environments, Mini 2 lowers the barrier to automation.

Contact UsMini 2 is the next evolution in compact collaborative robotics, offering double the payload and four times the acceleration of its predecessor – all while maintaining the same small footprint, intuitive setup, and affordable price.

Designed for SMEs and beyond, it brings faster cycle times, broader use cases, and seamless integration with the entire JAKA ecosystem.

From inspection and 3D vision tasks to high-speed handling in space-constrained environments, Mini 2 lowers the barrier to automation.

Product Features

Accelerated

Fast motion and short cycle times increase productivity in tight spaces.

01

Cost-Effective

Priced under €10,000 — ideal for SMEs starting or scaling automation.

02

Lightweight

Weighing under 10 kg, it's easy to move, install, and redeploy as needed.

03

Accelerated

Fast motion and short cycle times increase productivity in tight spaces.

Cost-Effective

Priced under €10,000 — ideal for SMEs starting or scaling automation.

Lightweight

Weighing under 10 kg, it's easy to move, install, and redeploy as needed.

Product Parameters

Weight (incl. cables)

9.9 kg

Programming

Graphic programming, drag and teach, SRCI, offline programming

Programming interface

Any graphical device: PC, tablet or smartphone

Nominal power consumption

180 W

Operating temperature

0–50°C

Tool I/O

2 digital outputs, 2 digital inputs, 2 analog inputs

I/O Ports

7 digital, I/O configurable

Communication

TCP/IP, Modbus TCP, Modbus RTU, Profinet, Ethernet/IP

Weight

1.1 kg (incl. accessories)

Series Products

Application Scenario

Inspection

Excellent compatibility, supporting integration with vision systems, measuring instruments, and other devices for non-destructive testing and fully automated high-precision measurement of diverse, small-batch parts.

Highly expandable, allowing companies to quickly achieve secondary deployment based on production needs.

Replaces manual inspection, enhancing efficiency and ensuring quality, freeing workers from repetitive tasks.

Sorting

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Handling

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.