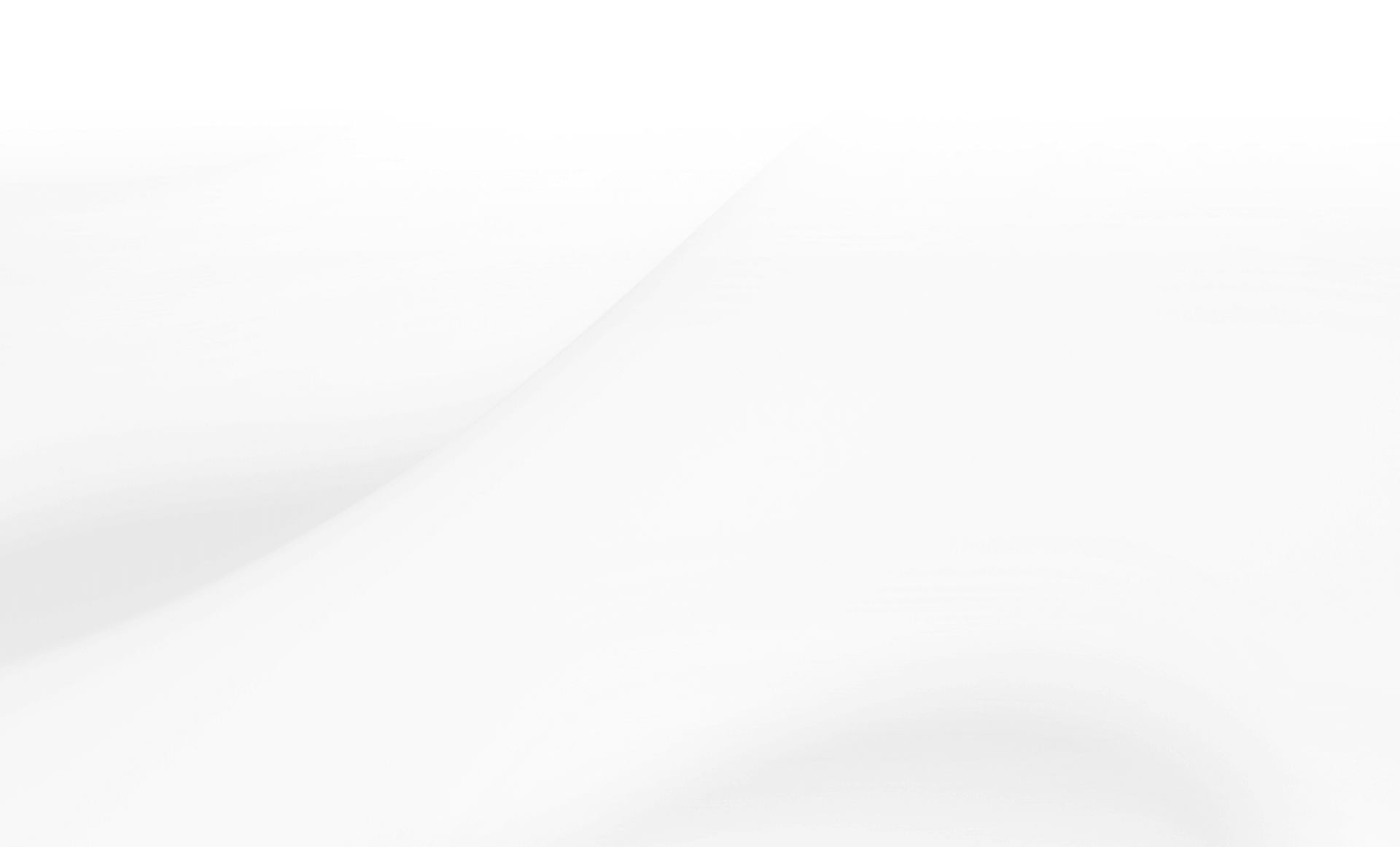

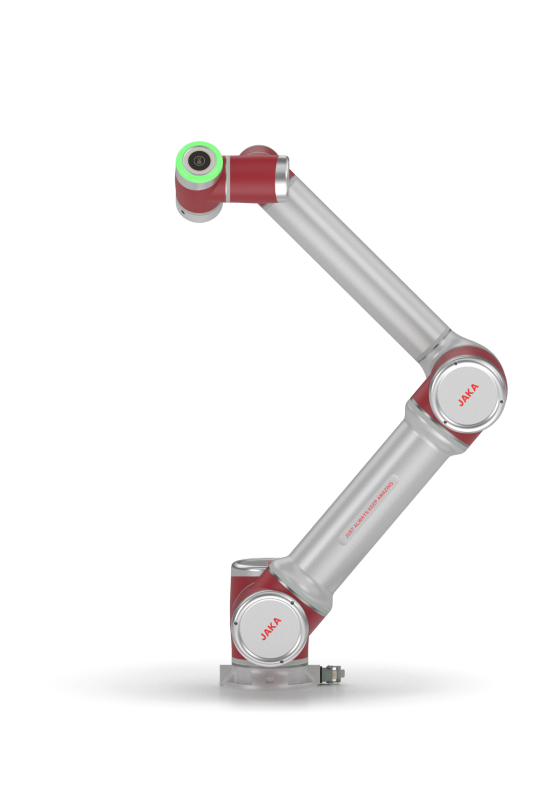

JAKA MiniCobo

Payload: 1 kg, Weight: 9,4 kg, Reach: 580 mm

Lightweight and easy to set up, MiniCobo seamlessly fits into a wide range of work environments — offering an excellent price-performance ratio and cost-efficient installation.

It's the perfect first step into robotic automation for both industrial and commercial applications,including handling,laboratory tasks,and retail environments.

Contact UsLightweight and easy to set up, MiniCobo seamlessly fits into a wide range of work environments — offering an excellent price-performance ratio and cost-efficient installation.

It's the perfect first step into robotic automation for both industrial and commercial applications,including handling,laboratory tasks,and retail environments.

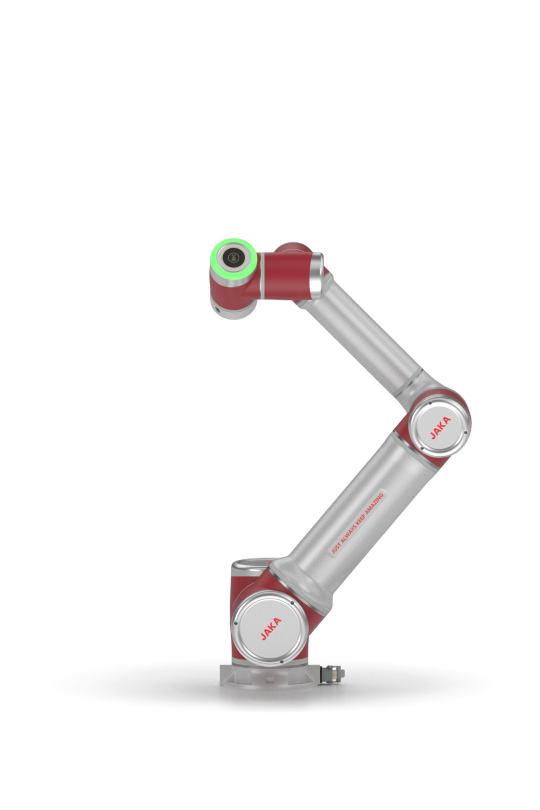

Product Features

Business-Ready

Compact, low-noise design. Perfect for education, retail, hospitality.

01

Cost-Effective

High-quality results with a low initial investment.

02

Lightweight

Weighing under 10 kg, it offers exceptional portability and convenience.

03

Business-Ready

Compact, low-noise design. Perfect for education, retail, hospitality.

Cost-Effective

High-quality results with a low initial investment.

Lightweight

Weighing under 10 kg, it offers exceptional portability and convenience.

Product Parameters

Maximum payload

1 kg (2.21 lb)

Weight (incl. cables)

9.4 kg (20.73 lb)

Accuracy

±0.1 mm(+0.003937 in)

Programming

Graphic programming, drag & teach, SRCI, offline programming

Programming interface

Any graphical device (PC, tablet, or smartphone)

Nominal power consumption

150W

Tool 1/O

2 Digital inputs;2 Digital outputs;2 Analog input

Base Diameter

124 mm (4.88 in)

Robot connection cable length

6 m (236 in)

l/0 ports

7-way port; Input and output configurable

Communication Protocols

TCP/P,Modbus TCP,Modbus RTU, Profinet, Ethernet/IP

Weight

About 1.7 kg (including accessories)

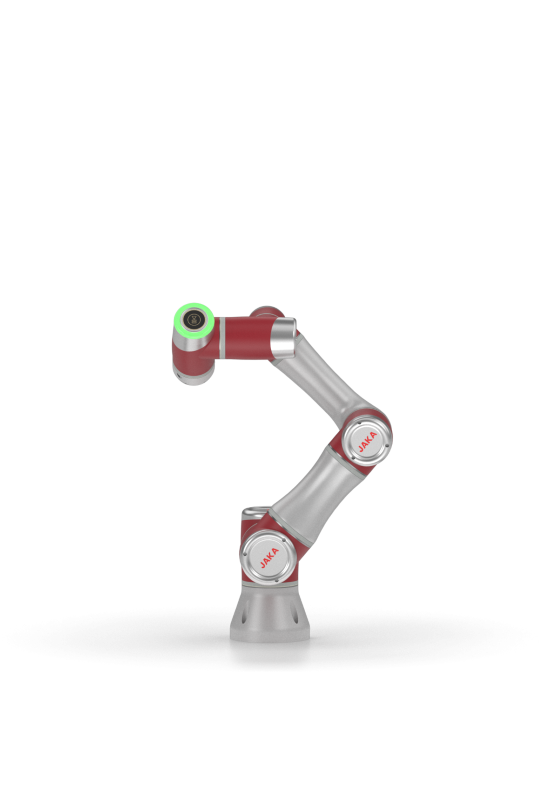

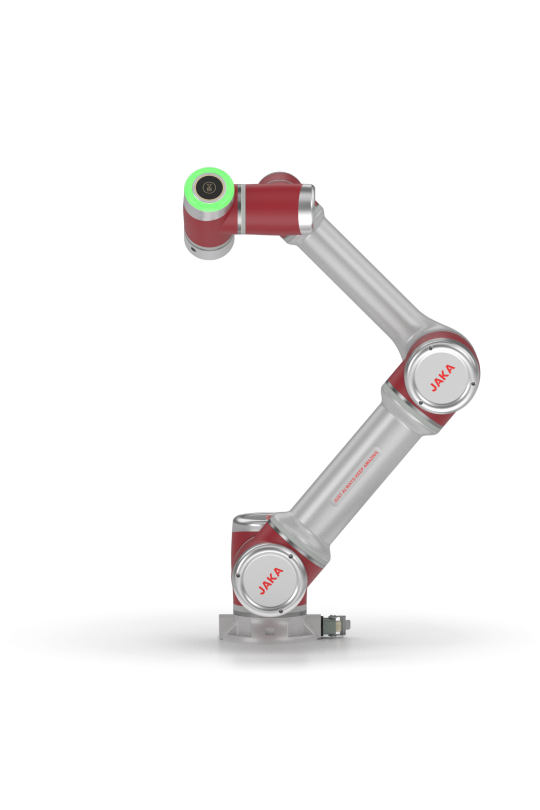

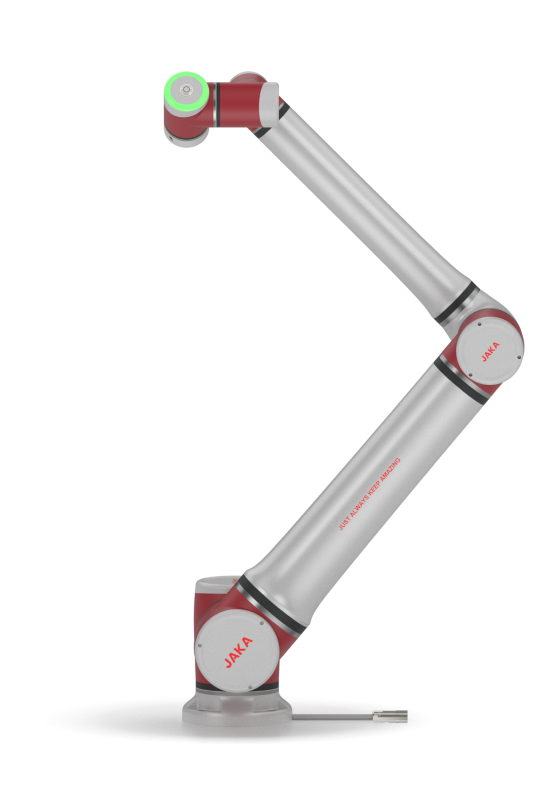

Series Products

Application Scenario

Loading and Unloading

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Flexible Assembly

High-precision adaptive assembly effectively prevents workpiece loss and increases productivity.

Lightweight design enables quick deployment on the production line.

Supports small-batch, multi-variety production.

Sorting

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Flexible Grasping

Lightweight design enables quick deployment on the production line.

Supports small-batch, multi-variety production.

High-precision adaptive assembly effectively prevents workpiece loss and increases productivity.

Inspection

Excellent compatibility, supporting integration with vision systems, measuring instruments, and other devices for non-destructive testing and fully automated high-precision measurement of diverse, small-batch parts.

Highly expandable, allowing companies to quickly achieve secondary deployment based on production needs.

Replaces manual inspection, enhancing efficiency and ensuring quality, freeing workers from repetitive tasks.