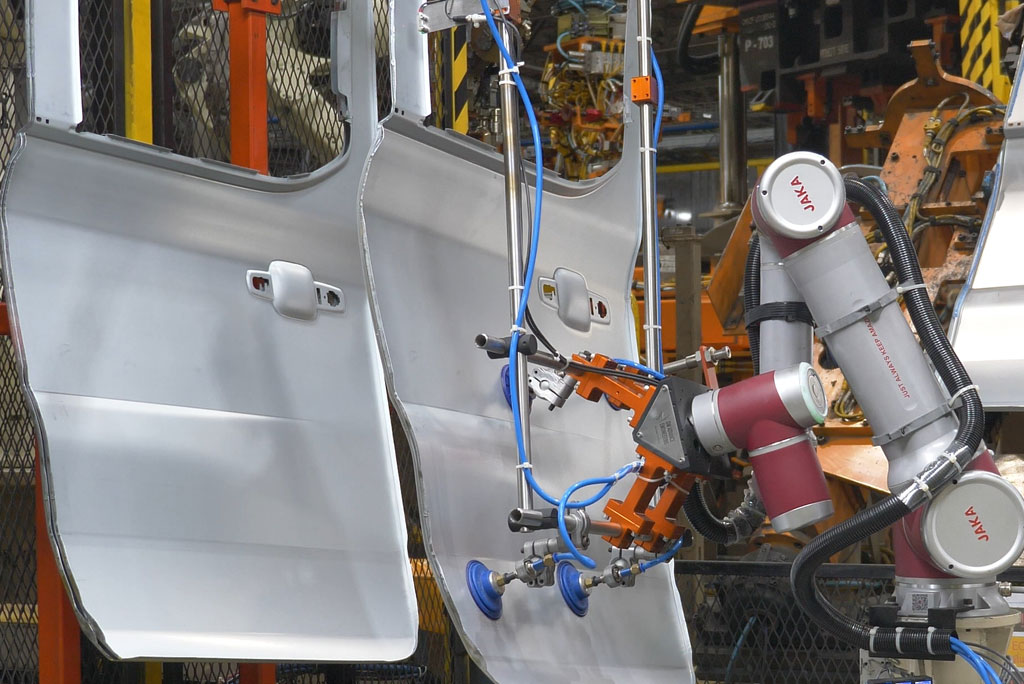

- Automotive

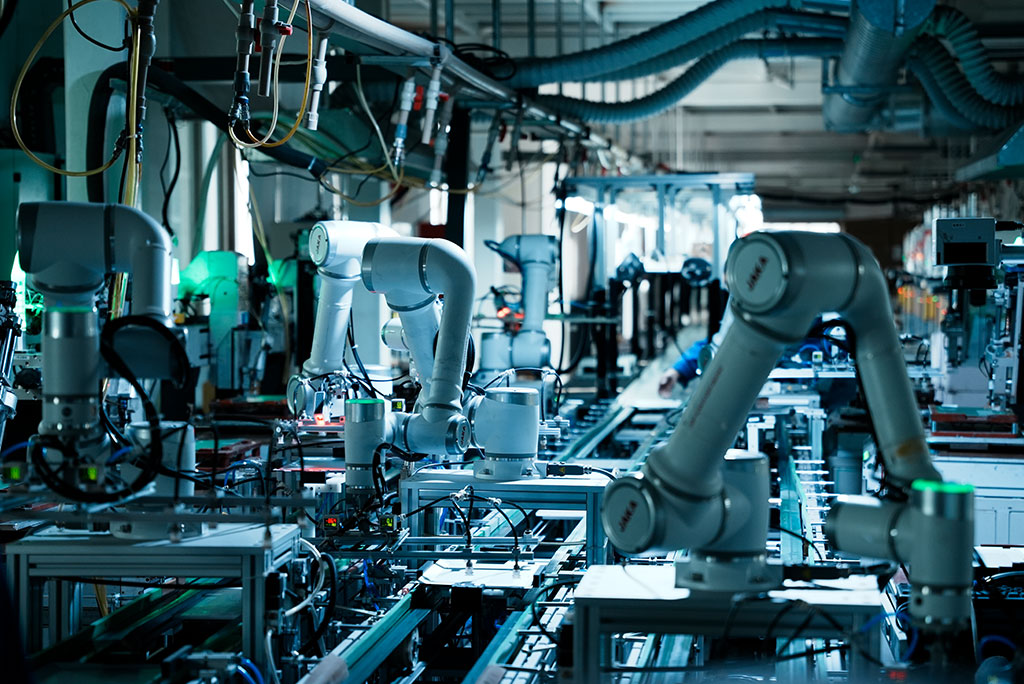

- Electronics

- Metal Manufacturing

Force control drag: Supports payloads from 3-18kg with force control sensors for smooth operation and handy point teaching.

Easy configuration: A new settings interface facilitates communication setup between the robot and welding machine. Safety interlock: Alarm signals between the robot and welding machine ensure reliable operation.

Manual control: Supports manual arc start/stop, gas feed/discontinuation, and step/continuous wire feeding.

Load and go: Simply load the arc welding process package via the app.

Debugging mode: Supports empty program run without arcing for easy verification of teaching points.

Versatile: Compatible with major domestic and international welding machine brands.

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Replaces manual labor, reduces management costs, effectively improves production rate

Can spray complex curves with precision control to save paint .

High-precision repeatability ensures product quality, reducing operational costs and minimizing reworked parts and scrapped parts.

A single robot can manage multiple production lines, significantly reducing costs

Compact structure, small footprint, high integration, and lightweight, effectively solving manual palletizing tasks on-site for customers.

Achieves automated palletizing, improves production efficiency, and enhances the working environment for operators.

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

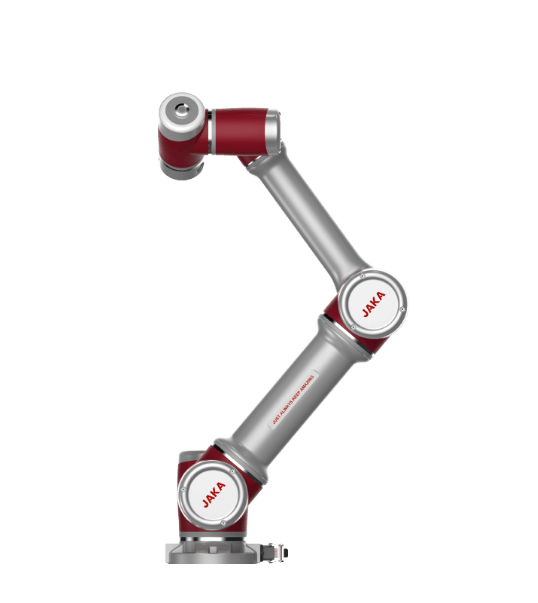

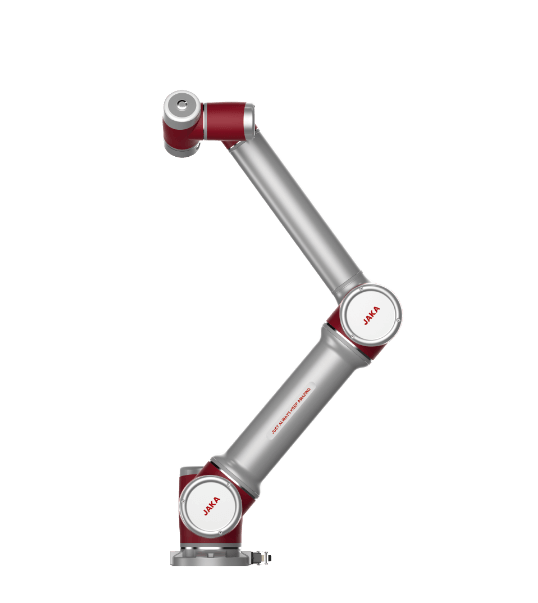

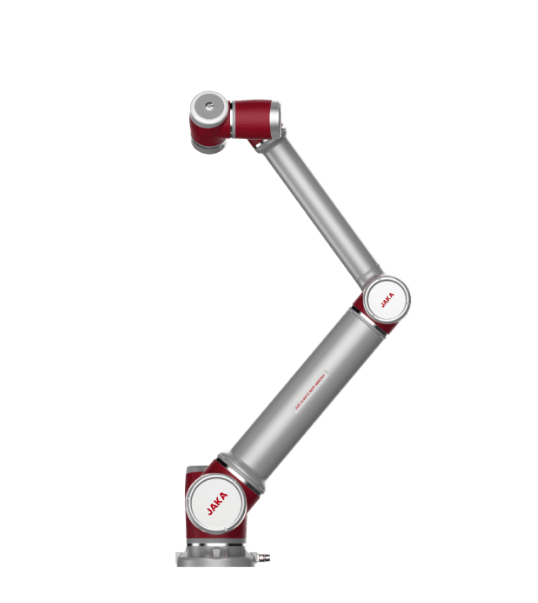

- JAKA Zu Series

- JAKA Zu3

- JAKA Zu5

- JAKA Zu7

- JAKA Zu12

- JAKA Zu18

- JAKA Zu20

- JAKA Zu30

- JAKA S Series

- JAKA S5

- JAKA S12

- JAKA Pro Series

- JAKA Pro5

- JAKA Pro12

- JAKA Pro16

- JAKA Mini Series

- JAKA MiniCobo

- JAKA Mini 2

- Vision Systems

- JAKA Lens 2D

Product Parameter Comparison

- JAKA Zu Series

- JAKA Zu3

- JAKA Zu5

- JAKA Zu7

- JAKA Zu12

- JAKA Zu18

- JAKA Zu20

- JAKA Zu30

- JAKA S Series

- JAKA S5

- JAKA S12

- JAKA Pro Series

- JAKA Pro5

- JAKA Pro12

- JAKA Pro16

- JAKA Mini Series

- JAKA MiniCobo

- JAKA Mini 2

- Vision Systems

- JAKA Lens 2D