- Products

- Solutions

- Service & Support

- JAKA+

- About JAKA

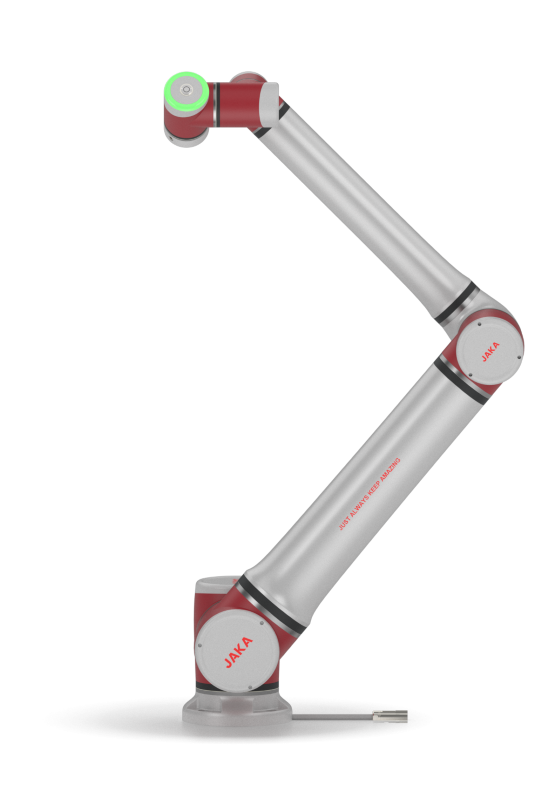

High efficiency, stability, and quality enable highly intelligent, automated screwdriving operations.

Torque adjustment range can be configured according to screwdriving product requirements, with each axis adjustable independently.

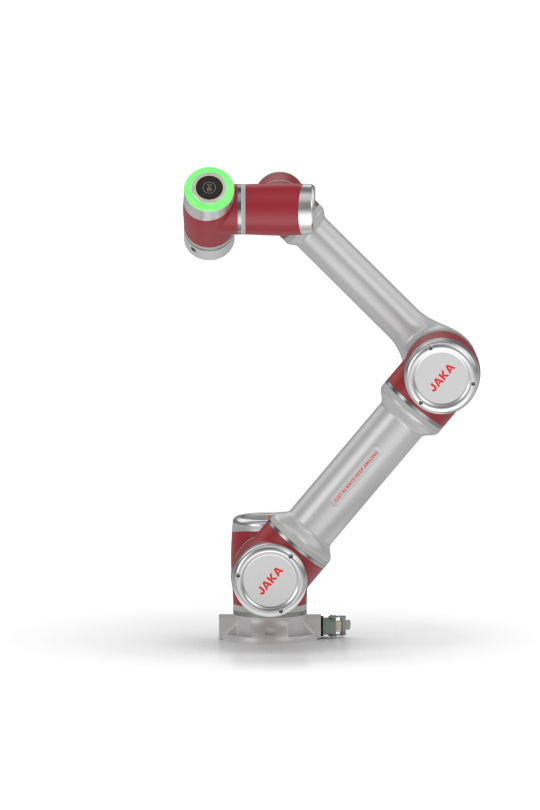

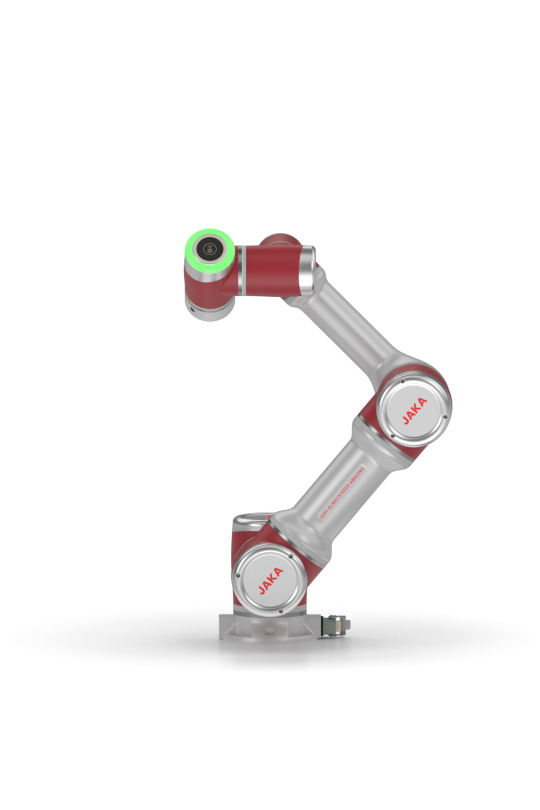

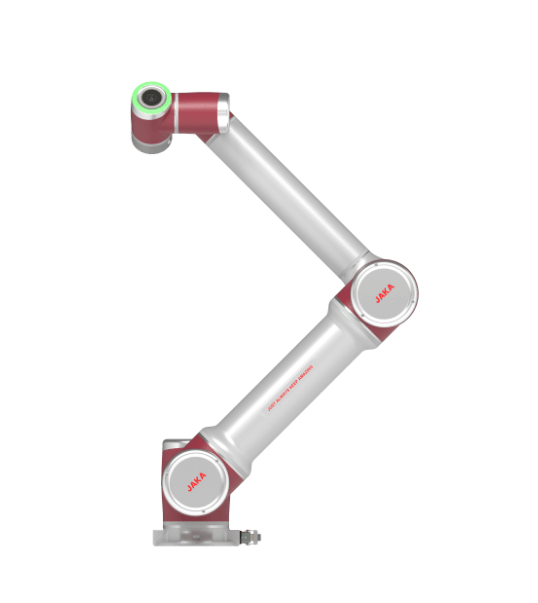

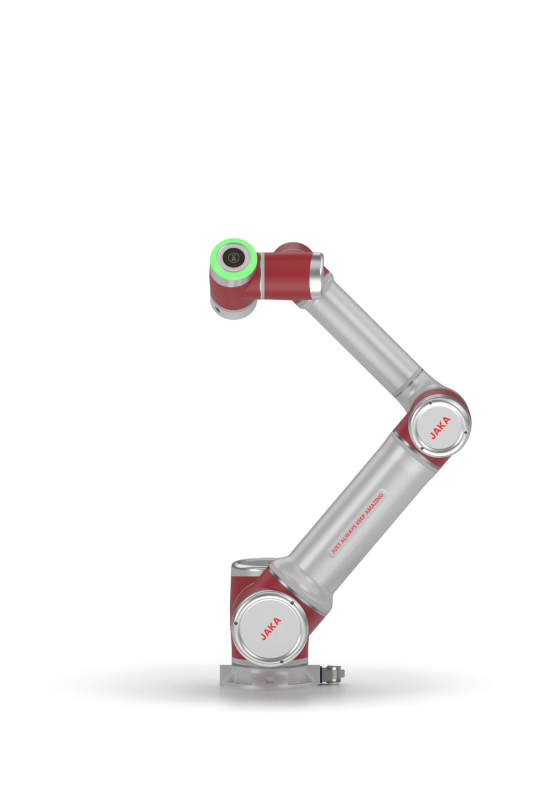

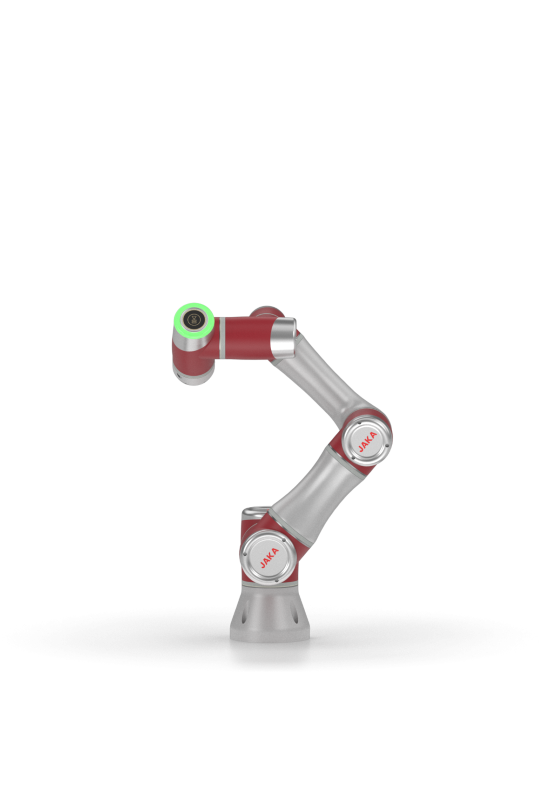

The operation of the JAKA‘s robots is quick and responsive.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Lightweight design enables quick deployment on the production line.

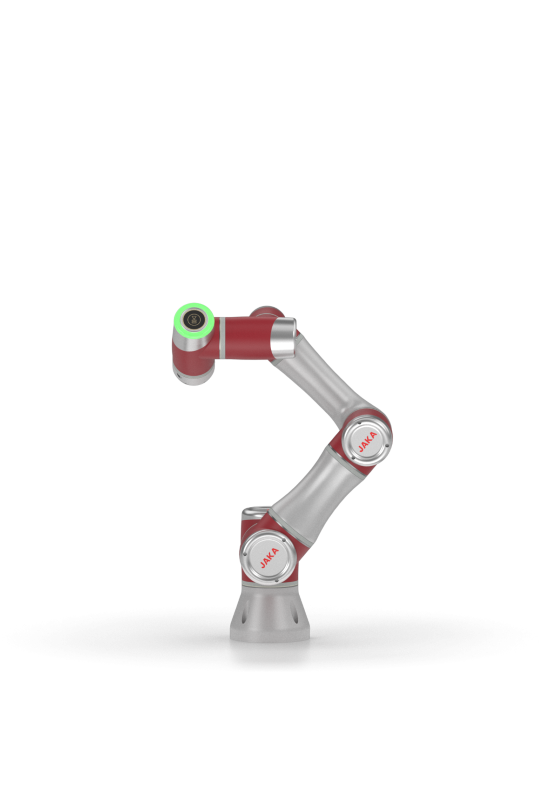

Supports small-batch, multi-variety production.

High-precision adaptive assembly effectively prevents workpiece loss and increases productivity.

Convenient and easy to use, easily movable within the working area, greatly enhancing flexibility and user experience.

Replaces manual dispensing, achieving mechanized production. Improves the appearance of dispensing, accurately controls flow, saves glue, reduces labor costs.

Highly expandable, allowing companies to quickly achieve secondary deployment based on production needs.

Replaces manual inspection, enhancing efficiency and ensuring quality, freeing workers from repetitive tasks.

Excellent compatibility, supporting integration with vision systems, measuring instruments, and other devices for non-destructive testing and fully automated high-precision measurement of diverse, small-batch parts.