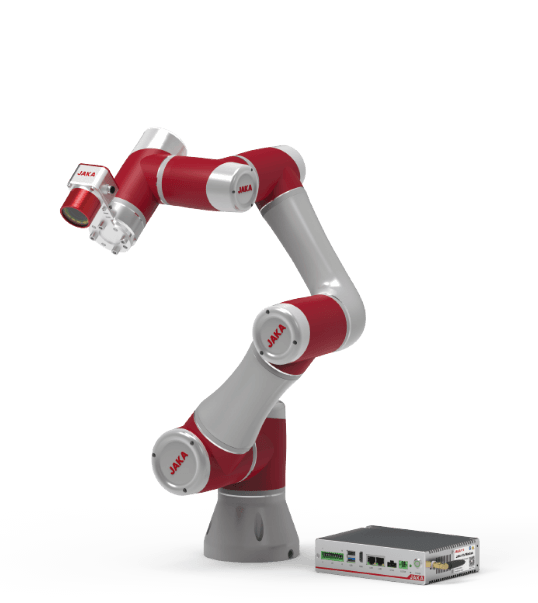

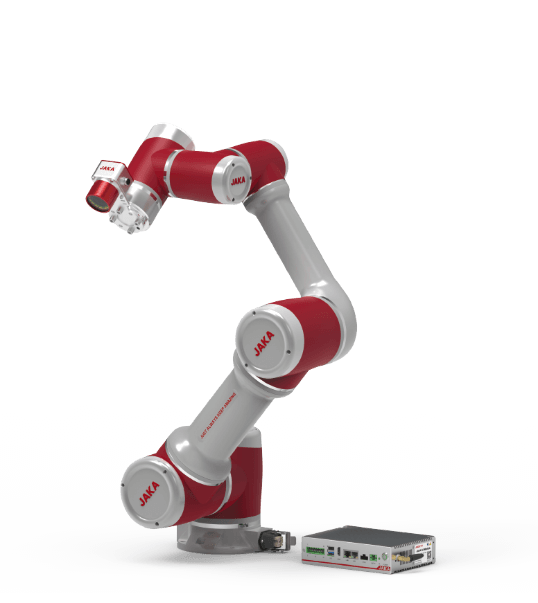

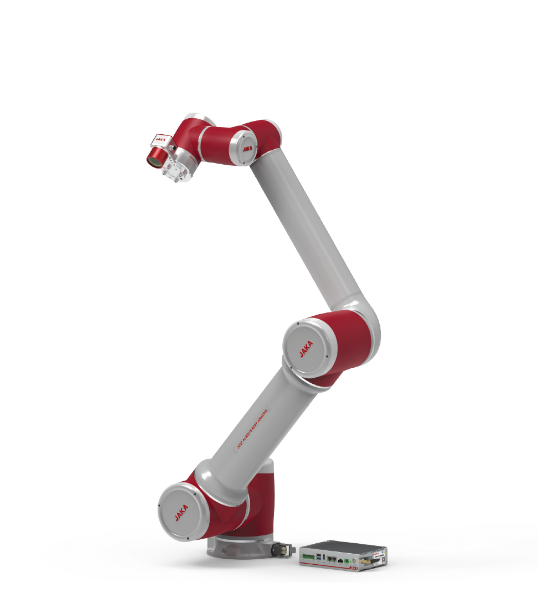

JAKA Ai5

JAKA All-in-one series collaborative robots with the S³ (Smart, Simple, Small) design principle

Features wireless teaching, graphical programming, and visual safety protection

Enhances safety in human-robot interaction and significantly lowers the usage threshold

Deep integration of vision for natural interaction and autonomous adaptation among robots, humans, and the environment, expanding application boundaries.

Contact UsJAKA All-in-one series collaborative robots with the S³ (Smart, Simple, Small) design principle

Features wireless teaching, graphical programming, and visual safety protection

Enhances safety in human-robot interaction and significantly lowers the usage threshold

Deep integration of vision for natural interaction and autonomous adaptation among robots, humans, and the environment, expanding application boundaries.

Product Features

Interactivity:

Integrated with wireless teaching, graphical programming, visual safety protection technologies, it revolutionizes the interaction between humans and robots.

01

Practicality:

The All-in-one series robots have deeply integrated vision, ensuring natural interaction and autonomous adaptation among robots, humans, and the environment.

02

Ease of Use

Enhanced safety in human-robot interaction, significantly lowering usage threshold

03

Safety

Innovative interaction methods enhance safety in human-robot collaboration

04

Interactivity:

Integrated with wireless teaching, graphical programming, visual safety protection technologies, it revolutionizes the interaction between humans and robots.

Practicality:

The All-in-one series robots have deeply integrated vision, ensuring natural interaction and autonomous adaptation among robots, humans, and the environment.

Ease of Use

Enhanced safety in human-robot interaction, significantly lowering usage threshold

Safety

Innovative interaction methods enhance safety in human-robot collaboration

Product Parameters

Weight (including cables)

23 kg (50.71 lb)

Repeatability

+0.02 mm (±0.00079 in)

Degree of freedom

Graphical programming, and freedrive programming

Programming

Mobile terminal (computer/pad/mobile phone)

Footprint

158 mm (6.220 in)

Humidity

2 digital inputs/

2 digital outputs/

2 analog inputs

l/0 ports

7-way port; Input and output configurable

Communication mode

TCP/P,Modbus TCP,Modbus RTU, Profinet, Ethernet/IP

Weight

About 1.7 kg (including accessories)

Lens focal length

8 mm/16 mm

Vision

>70mm*50mm/>35mm*25mm

Precision

>0.08 mm/>0.04 mm

Communications interface

Etheret interface (TCP/lP protocol)

Series Products

Application Scenario

Loading and Unloading

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Screwdriving

Torque adjustment range can be configured according to screwdriving product requirements, with each axis adjustable independently.

The operation of the JAKA‘s robots is quick and responsive.

High efficiency, stability, and quality enable highly intelligent, automated screwdriving operations.

Flexible Assembly

Supports small-batch, multi-variety production.

High-precision adaptive assembly effectively prevents workpiece loss and increases productivity.

Lightweight design enables quick deployment on the production line.

Adhesive Application

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.

Inspection

Replaces manual inspection, enhancing efficiency and ensuring quality, freeing workers from repetitive tasks.

Excellent compatibility, supporting integration with vision systems, measuring instruments, and other devices for non-destructive testing and fully automated high-precision measurement of diverse, small-batch parts.

Highly expandable, allowing companies to quickly achieve secondary deployment based on production needs.