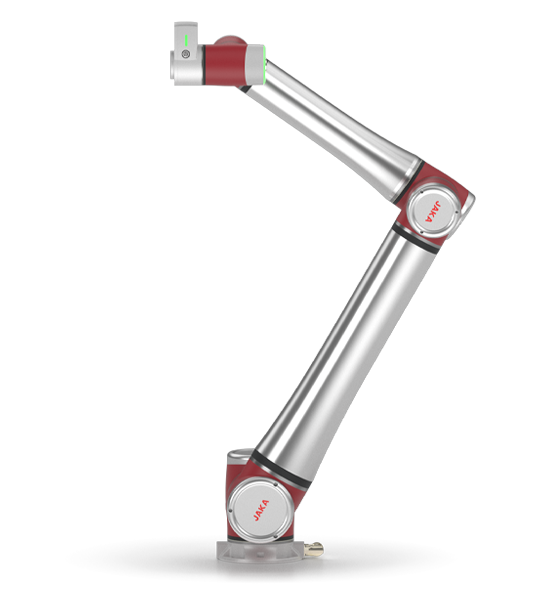

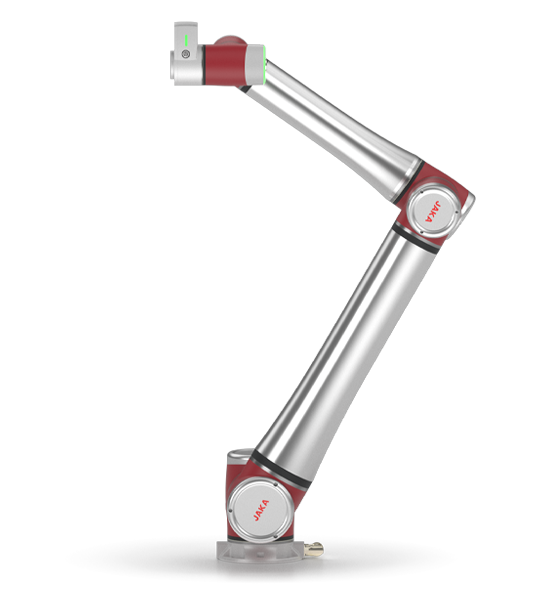

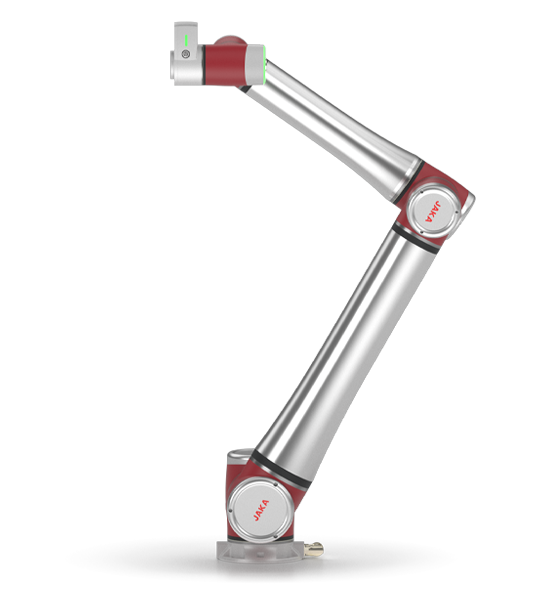

JAKA A12L

Intelligent Visual Perception Robot

It combines collaborative robot and intelligent vision

The new-generation visual perception robot enables users to see results easily.

Contact UsIntelligent Visual Perception Robot

It combines collaborative robot and intelligent vision

The new-generation visual perception robot enables users to see results easily.

Product Parameters

Repeat Positioning Accuracy

±0.03mm

Degrees of Freedom (DoF)

6

Programming

Graphical Programming, Drag-and-Drop Programming

Teach Pendant Type

Mobile Terminals (Computer, Tablet, Mobile Phone)

Control Cabinet Model

CAB L

Power Supply

100-240AVC 50~60HZ

Operating Temperature

0~50掳C

Installation Method

Floor-standing, Wall-mounted

IO Interface

16DI (configurable NPN/PNP); 16DO (configurable NPN/PNP mode); 16CI (default safety mode, PNP); 16CO (default safety mode, PNP)

IO Power Supply

Internal: 24V-3A; External: 24V-5A

Communication Interface

2*Ethernet (Gigabit) RS485 (Master/Slave) TCP/IP Ethercat (Master) Ethernet/IP (Slave) Profinet (Slave) *Supports Expansion (Profinet Master, CC-Link Slave, Powerlink Master, E/P Master, Ethercat Slave)

IP Classification

IP54 (End Joints 5/6: IP67)

Tool I/O Ports

2 Digital Inputs, 2 Digital Outputs, 2 Analog Inputs

Resolution

34562880 (switchable to 24002000)

Lens Interface

M12, Auto Focus

Lens Focal Length

Standard 12mm, Optional 8mm/16mm

Light Source Type

Standard White Light, Optional Red/Blue, Polarized/Non-polarized

Communication Interface

Gigabit Ethernet

Power Supply

Supports 9~26VDC, 1A Input, Adaptable to Industrial Voltage Environment

Operating Temperature

20%~95%, No Condensation

Storage Temperature

-30°~70°

Series Products

Application Scenario

Loading and Unloading

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Inspection

Highly expandable, allowing companies to quickly achieve secondary deployment based on production needs.

Replaces manual inspection, enhancing efficiency and ensuring quality, freeing workers from repetitive tasks.

Excellent compatibility, supporting integration with vision systems, measuring instruments, and other devices for non-destructive testing and fully automated high-precision measurement of diverse, small-batch parts.

Sorting

Highly reprogrammable, allowing users to adapt programming for different workpieces, shortening the product modification cycle and reducing associated equipment investment.

The robot replaces manual operators, minimizing direct contact with hazardous processing equipment, thus reducing the occurrence of accidents.

Ensure consistent processing precision, guarantee reliable quality, and reduce the defect rate.