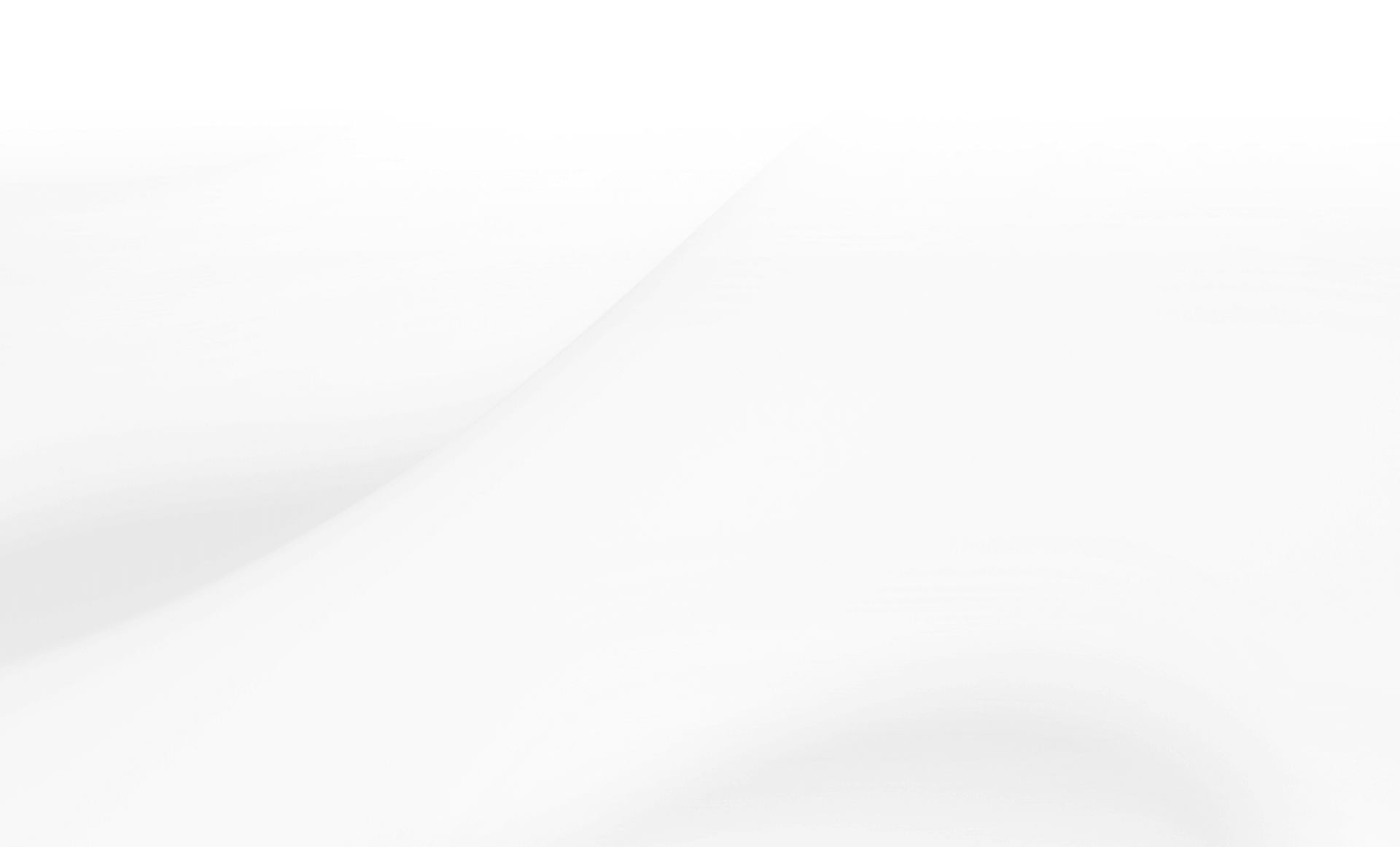

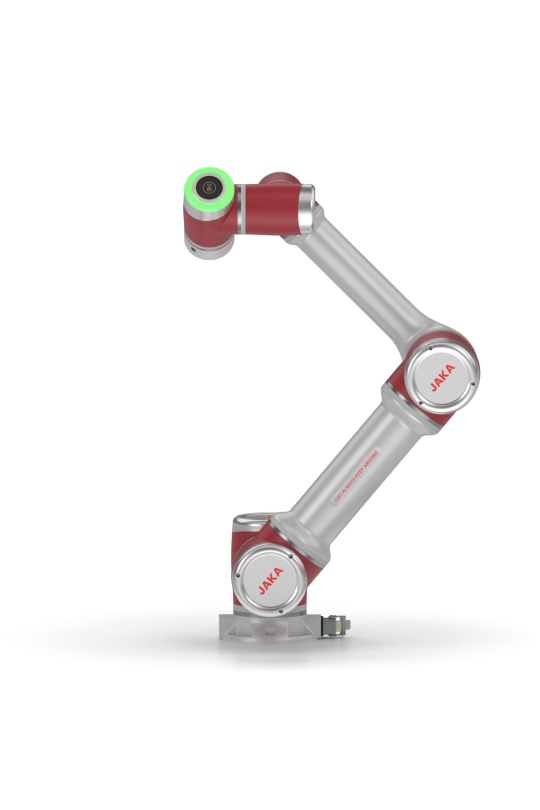

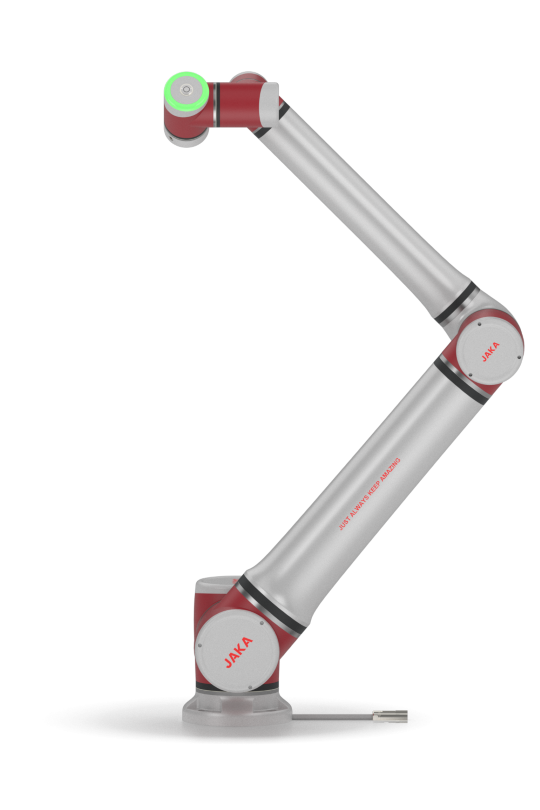

JAKA Zu30

Payload: 30 kg, Weight: 65 kg, Reach: 1350 mm

A groundbreaking innovation designed specifically for heavy-load handling and collaborative scenarios with limited space. Upholding the consistent ease of use, safety, and outstanding performance of the JAKA Zu series, it features a powerful 30 kg payload capacity, a 1350 mm reach, and a ±0.05 mm repeat positioning accuracy, paired with IP65 high-level protection to break through the application boundaries of collaborative robots. Whether it is heavy-load handling, precise loading and unloading of wafer pods, machining of heavy workpieces, efficient palletizing, or precision welding, the JAKA Zu 30 creates a tailored ideal solution for you and leads the new era of collaborative automation in the future!

Contact UsA groundbreaking innovation designed specifically for heavy-load handling and collaborative scenarios with limited space. Upholding the consistent ease of use, safety, and outstanding performance of the JAKA Zu series, it features a powerful 30 kg payload capacity, a 1350 mm reach, and a ±0.05 mm repeat positioning accuracy, paired with IP65 high-level protection to break through the application boundaries of collaborative robots. Whether it is heavy-load handling, precise loading and unloading of wafer pods, machining of heavy workpieces, efficient palletizing, or precision welding, the JAKA Zu 30 creates a tailored ideal solution for you and leads the new era of collaborative automation in the future!

Product Features

High ingress protection

03

Product Parameters

Weight (including cables)

65 kg (149.9 lb)

Repeatability

±0.05 mm (±0.00120 in)

Degree of freedom

Graphical programming, and freedrive programming

Programming

Mobile terminal (computer/pad/mobile phone)

Humidity

2 digital inputs/

2 digital outputs/

2 analog inputs

Footprint

246 mm (9.685 in)

l/0 ports

16 digital inputs, 16 digital outputs, 2 analog inputs or outputs

Communication mode

TCP/IP,Modbus TCP,Modbus RTU, Profinet, Ethemet/lP

Power supply

100-240VAC,50-60Hz

Size

410×307×235 (mm) (W×H×D)

Series Products

Application Scenario

Welding

Load and go: Simply load the arc welding process package via the app.

Manual control: Supports manual arc start/stop, gas feed/discontinuation, and step/continuous wire feeding.

Debugging mode: Supports empty program run without arcing for easy verification of teaching points.

Versatile: Compatible with major domestic and international welding machine brands.

Force control drag: Supports payloads from 3-18kg with force control sensors for smooth operation and handy point teaching.

Easy configuration: A new settings interface facilitates communication setup between the robot and welding machine. Safety interlock: Alarm signals between the robot and welding machine ensure reliable operation.

Packing

Replaces manual labor, reduces management costs, effectively improves production rate

Can spray complex curves with precision control to save paint .

High-precision repeatability ensures product quality, reducing operational costs and minimizing reworked parts and scrapped parts.

Loading and Unloading

Quickly complete secondary deployment of the production line, achieving efficient, high-quality, and flexible machine tending by robots.

Simple programming allows for easy control of the robot, maximizing the replacement of labor and freeing up workforce.

Enhances production efficiency and product quality.

Palletizing

A single robot can manage multiple production lines, significantly reducing costs

Compact structure, small footprint, high integration, and lightweight, effectively solving manual palletizing tasks on-site for customers.

Achieves automated palletizing, improves production efficiency, and enhances the working environment for operators.