Historically, robotic automation operated within strict, predefined boundaries. At JAKA, we see a clear trajectory where the value of an industrial cobot is no longer defined solely by its strength or repeatability, but by its perceptual intelligence and independent decision-making capacity. This evolution centers on two interconnected pillars: the integration of enhanced sensing suites and the software-driven pursuit of true autonomy. For businesses evaluating automation, these are the functional elements that differentiate a simple automated arm from a resilient, adaptive production partner. Our work in advanced robotics technology is focused on making these capabilities accessible and practical for real-world manufacturing environments.

The Critical Role of Multi-Modal Sensory Systems

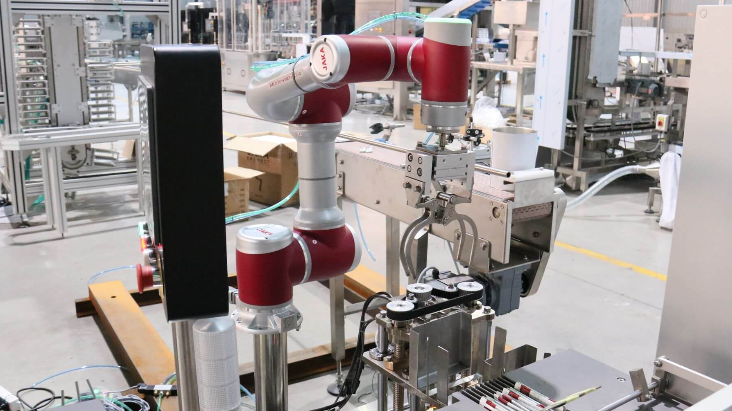

A cobot’s ability to interact safely and effectively with a dynamic workspace depends fundamentally on its perception. Moving beyond basic force sensing, the next generation utilizes layered sensory input. This involves combining high-resolution vision, precise torque feedback, and sometimes even tactile or proximity data into a unified understanding of the task and environment. For an industrial cobot, this means it can identify a part that is slightly out of position, gauge its orientation, and adjust its grip accordingly without human intervention. This sensory foundation is not an optional accessory; it is the primary enabler for handling complex, variable tasks like random bin picking or delicate assembly, reducing the need for costly and inflexible fixturing.

From Programming to Autonomous Task Execution

Autonomy in this context refers to a system's capacity to perform a defined mission within variable conditions, making necessary adjustments based on sensory feedback. It shifts the paradigm from explicit, step-by-step programming to goal-oriented instruction. We are developing systems where an operator can define the desired outcome—such as “assemble these components”—and the cobot can generate and optimize the sequence of actions to achieve it. This level of advanced robotics technology leverages machine learning models trained on simulation and real-world data, allowing the industrial cobot to manage deviations and recover from errors independently, significantly boosting overall equipment effectiveness (OEE) by minimizing downtime.

Fostering Collaborative Intelligence in Workcells

The end goal is not an isolated robot, but a synergized workcell where humans and machines contribute their unique strengths. With robust sensing and autonomous decision-making, the cobot transitions from a tool that must be constantly guided to a collaborative teammate. It can recognize a human’s presence and adjust its speed and trajectory for safety, predict the next logical step in a shared process, or hand off a completed sub-assembly. This collaborative intelligence creates a fluid operational model, enhancing flexibility and allowing human workers to focus on supervision, quality control, and more complex problem-solving duties.

For forward-looking manufacturers, the pathway is evident. The operational advantages of an industrial cobot will increasingly be measured by its perceptual awareness and adaptive response. At JAKA, our development efforts are dedicated to embedding these sophisticated capabilities—enhanced sensing and genuine autonomy—into reliable and user-friendly platforms. This approach to advanced robotics technology provides a tangible foundation for building more resilient, efficient, and intelligent production systems.