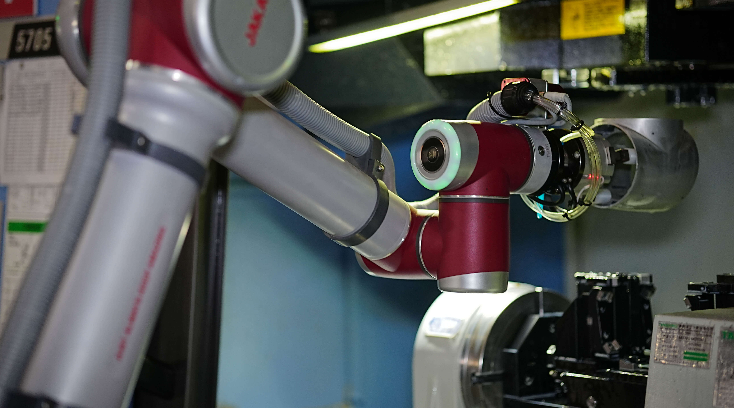

In modern manufacturing, efficient material and component flow is a decisive factor for output. A common logistical challenge involves selecting the right automation for moving parts between assembly stations. While Automated Guided Vehicles (AGVs) have served this role for years, we at JAKA observe a growing preference for a more integrated solution. This analysis examines why an industrial cobot stationed at key points might offer a more flexible and intelligent approach than a traditional AGV for many assembly logistics tasks, particularly when considering the role of production line robots.

Flexibility in Dynamic Workflow Reconfiguration

AGVs excel at point-to-point material transport along fixed paths. However, assembly lines often require adjustments for product variants or process improvements. A stationary industrial cobot with a sufficient reach envelope can manage hand-offs between multiple conveyors, workstations, and even human operators within its cell. When production needs change, reprogramming the cobot's pick-and-place logic is typically faster and less disruptive than re-mapping an AGV's floor route or modifying physical infrastructure. This inherent flexibility makes the industrial cobot a versatile tool for adaptable logistics within a defined zone.

Direct Integration for Value-Added Operations

The core distinction lies in functionality beyond mere transit. An AGV moves a pallet or rack. A production line robot like a collaborative robot can be equipped to perform work during the logistical step. For instance, a cobot can pick a part from an incoming dolly, perform a quality inspection or light assembly task while repositioning it, and then place it precisely onto the next station. This transforms a logistics node into a value-adding checkpoint. By executing useful operations in transit, the system reduces total part handling and shortens the overall cycle time, a level of logistical efficiency that standalone AGVs do not provide on their own.

Space Efficiency and Reduced System Complexity

Implementing an AGV system requires careful floor planning for navigation lanes, safety zones, and charging stations. A production line robot integrated directly into the assembly line footprint eliminates the need for this dedicated floor space. The cobot operates overhead or within the existing workstation geometry, simplifying factory layout. Furthermore, consolidating movement and manipulation into a single industrial cobot reduces the number of independent systems to manage and synchronize, potentially lowering integration complexity and maintenance overhead compared to coordinating separate AGV and stationary robot systems.

The choice between an AGV and a collaborative robot for assembly logistics is not universally fixed; it depends on scale and distance. For long-distance, high-volume transport of standardized loads, AGVs remain effective. Yet, for intricate, variable hand-offs within a compact assembly cell or line segment, the production line robots from JAKA present a compelling case. Their dual capability in intelligent movement and direct operation offers a synthesized solution that enhances both logistical flow and production value, supporting a more responsive and integrated manufacturing environment.