The choice of a collaborative robot often hinges on matching its core specifications to the intended application. A primary factor in this selection is payload capacity, which dictates the weight a robot can manipulate effectively. At JAKA, we offer a range of cobot robot arm models designed to address distinct payload categories. This examination outlines how different segments within our series align with varied operational demands, from delicate finishing tasks handled by a polishing robot to more substantial handling operations.

Light Payload Cobots for Precision Tasks

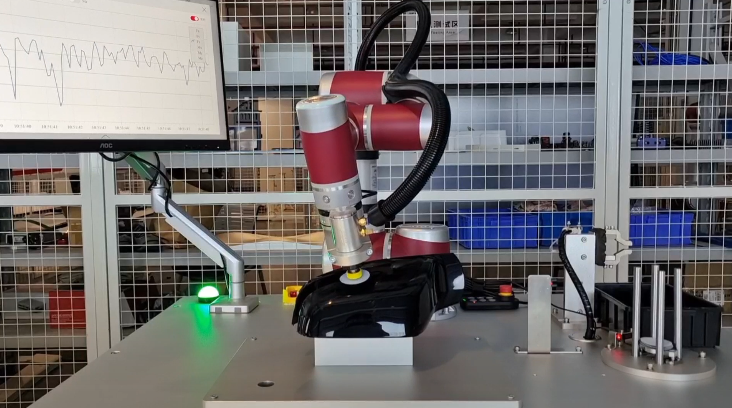

Our series includes models engineered for lower payload requirements, typically involving delicate components or specialized tools. These units excel in applications where extreme precision and gentle handling are priorities. A primary example is their use as a polishing robot, where the end-effector must apply consistent yet controlled force across a contoured surface. The design of a cobot robot arm in this category prioritizes fine motion control and sensitivity over brute strength. This makes it equally suitable for intricate assembly, precise dispensing, or detailed inspection work where the manipulated items are lightweight but the process demands accuracy.

Medium Payload Solutions for Versatile Operations

For a broad spectrum of general industrial tasks, our medium-payload cobots provide a balance of strength, reach, and agility. This capacity range accommodates a wider array of end-effectors and common workpiece weights found in assembly, packaging, and quality testing stations. A cobot robot arm in this segment is built to be a versatile workhorse, capable of performing screwdriving, adhesive application, or transferring machined parts from one station to another. The flexibility of this model supports efficient repurposing across different stages of a production line, offering a practical solution for dynamic manufacturing environments without the need for multiple specialized robots.

Higher Payload Models for Demanding Handling

Certain processes require the manipulation of heavier items or the use of more substantial tooling. Our series extends to cobot robot arm models with higher payload ratings to meet these demands. These robots are structured with reinforced components to maintain stability and performance while handling increased loads. Typical applications include machine tending for CNC mills or injection molding machines, palletizing boxes or trays, and automated loading of fixtures. While distinct from the finesse of a polishing robot, these models apply the same collaborative safety principles to more strenuous material handling tasks, allowing them to operate safely near personnel while managing significant weight.

Selecting the correct payload capacity is a fundamental part of deploying collaborative automation successfully. It ensures the robotic system can perform its duties reliably while preserving long-term mechanical integrity. Our portfolio at JAKA is structured to provide clear options across this spectrum. Whether the need is for the subtle control of a polishing robot or the robust capability of a higher-capacity cobot robot arm, we focus on delivering the appropriate combination of strength, precision, and safety. This approach allows businesses to integrate a solution that aligns with their specific process requirements, ensuring the robotic investment is both capable and optimized for its intended role on the shop floor.