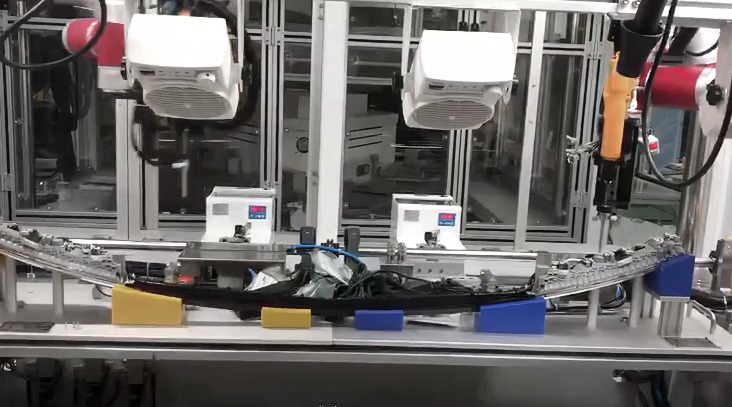

Manufacturing operations constantly evaluate methods to improve output and workplace conditions. The choice between automated and manual techniques is particularly clear in repetitive fastening tasks. Introducing a screwdriving robot into an assembly line represents a shift in operational methodology. At JAKA, we observe how this technology compares to human effort across three measurable parameters: the pace of operation, the uniformity of output, and the physical impact on workers. This analysis also reflects principles applied in other precise tasks, such as those performed by a polishing robot.

Operational Rhythm and Cycle Time

The pace of manual screwdriving is governed by human endurance and variability. A worker may begin a shift at high speed, but that rate naturally fluctuates with fatigue, distraction, or the need to handle minor issues. A screwdriving robot, once programmed, operates at a consistent, repeatable cycle time without interruption. It does not require breaks, maintaining the same pace hour after hour. This constant rhythm allows for highly predictable production scheduling and output calculations. The reliability in motion is akin to that of a polishing robot, where unvarying repetition is fundamental to the result.

Output Uniformity and Defect Reduction

Consistency in torque and placement is a primary advantage of automation. Manual assembly can lead to variations—a fastener may be under-tightened, over-tightened, or cross-threaded due to human error or tool calibration drift. A screwdriving robot applies the programmed torque and angle consistently, significantly reducing the occurrence of common fastening defects. This level of repeatability enhances product quality, reduces waste from rework or scrap, and strengthens compliance with stringent production standards. It is a principle of precision that mirrors the consistent pressure and path control required from a polishing robot for a flawless finish.

Workplace Design and Physical Impact

The ergonomic aspect presents a substantial contrast. Manual screwdriving, especially overhead or in tight spaces, is a recognized source of repetitive strain injuries, leading to discomfort, absenteeism, and potential long-term health issues for staff. Deploying a screwdriving robot removes the human operator from this physically taxing activity. The worker is then reassigned to a role involving supervision, quality inspection, or machine tending, which typically involves less biomechanical stress. This reallocation improves the overall work environment and aligns with a focus on human-centric manufacturing, a consideration also relevant when implementing a polishing robot for tasks involving forceful, repetitive motion.

The comparison underscores a shift from variable human labor to controlled mechanical execution. Automation in tasks like fastening provides distinct outcomes in production velocity, quality assurance, and workforce well-being. The consistent performance of a screwdriving robot addresses limitations inherent in manual methods. For businesses assessing this transition, the evaluation extends beyond simple substitution to considering system redesign and human resource redeployment. At JAKA, we provide the robotic technology that enables this change. Our expertise supports the integration of systems that deliver repeatable precision, allowing human talent to focus on more complex, value-added activities within a safer and more sustainable operational framework.