Collaboration defines the modern automated workspace, yet the complete removal of physical safeguarding requires careful justification. The integration of a collaborative factory robot arm introduces advanced force and speed monitoring, but these features do not universally eliminate all traditional safety measures. We at JAKA approach this question through the lens of risk assessment, not assumption. The decision to operate a cobot without barriers hinges on specific task parameters, the surrounding environment, and the nature of human interaction. This analysis outlines key situations where perimeter safeguarding for a factory robot arm remains a critical component of a safe system.

The Foundation of a Comprehensive Risk Assessment

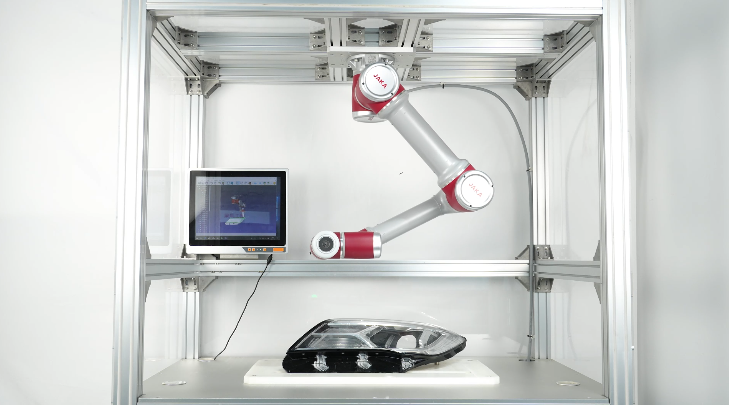

A documented risk assessment, aligned with applicable standards, is the mandatory first step before any barrier removal. This process must evaluate the entire application of the factory robot arm, including all tools, workpieces, and peripheral equipment. Even a cobot with power and force limiting (PFL) capabilities can present hazards if it handles sharp, heavy, or hot components. The assessment must scrutinize not only the robot itself but the process it enables. For instance, a polishing robot may use abrasive wheels or generate significant airborne particulates, creating hazards that exist independently of the robot's collaborative motion.

Inherent Process Hazards and Peripheral Equipment

Certain automated tasks generate inherent risks that physical barriers help mitigate. A polishing robot application often involves high-speed rotary spindles and abrasive media. While the factory robot arm may stop upon contact, the tool itself could cause lacerations or project debris. Similarly, processes involving molten material, chemicals, or lasers introduce dangers that safeguarding must contain. In these contexts, the barrier protects personnel from the process hazard, while the cobot's collaborative features address the risk of impact from the arm's movement itself. The safety system is therefore layered, addressing multiple sources of potential harm.

Workspace Design and Unpredictable Human Interaction

The intended collaborative workspace design directly influences barrier necessity. True collaboration, where a human and robot work simultaneously on the same part or fixture within a shared, defined zone, often utilizes the cobot’s built-in safety monitors as the primary safeguard. However, in areas where human presence is sporadic or unpredictable—such as a walkway adjacent to the robot’s full range of motion—a physical barrier may be the most reliable method to prevent accidental entry into the operating envelope. This is especially pertinent for a polishing robot or other tasks where the arm’s movement path is wide, repetitive, and could intersect with an unexpected pedestrian route.

The question of barriers is not settled by the collaborative classification of the factory robot arm alone. It is resolved through a systematic evaluation of the total system risk. We believe that effective safety integrates the cobot’s advanced sensors with thoughtful workspace design and, where justified by the identified hazards, appropriate physical safeguarding. For processes like those performed by a polishing robot, where tools and byproducts pose separate risks, a combined approach ensures true operational safety. The goal is a secure, efficient workspace where human and machine can interact productively, supported by the right protective measures.