In applications where microscopic precision defines success, the mechanical potential of a servo arm robot is only realized through meticulous calibration. This process directly dictates the system's repeatability and positional accuracy, factors that become critical in tasks like precision finishing. At JAKA, we address calibration not as a single setup procedure but as an ongoing discipline essential for performance. For a polishing robot tasked with achieving a perfect surface finish, or any servo arm robot in high-tolerance assembly, advanced calibration is the foundation of reliable results.

Mechanical and Kinematic Parameter Calibration

The initial layer of calibration involves the robot's internal model of itself. Each servo arm robot is built to precise specifications, but minute variations in joint alignment and link dimensions exist. Advanced calibration techniques map these parameters by moving the arm through a programmed sequence and measuring the variance between the commanded and actual end-effector position using external metrology tools. Compensating for these kinematic errors in the controller's software ensures the robot's movement matches its theoretical model. This foundational step elevates the native accuracy of the system, which is a prerequisite for any high-precision application, whether it involves delicate assembly or the precise path control required by a polishing robot.

Tool Center Point and Workspace Referencing

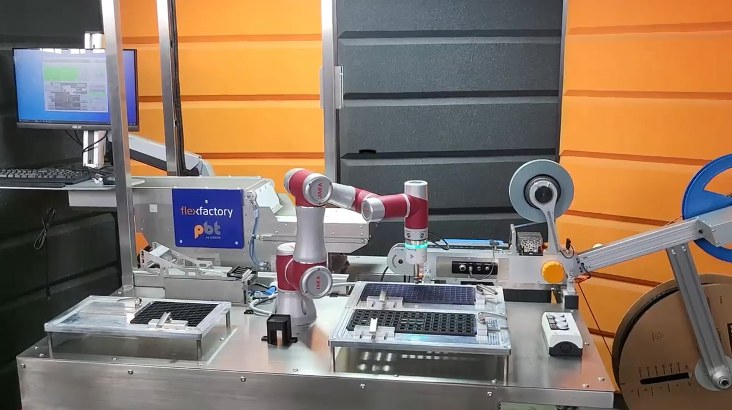

With an accurate arm, focus shifts to the tool and its environment. The Tool Center Point (TCP) must be defined with exceptional precision. For a polishing robot, the TCP is the active contact point of the spindle or tool; an error of a few millimeters can cause uneven material removal or part damage. Advanced methods go beyond simple manual teaching, utilizing calibration spheres or laser systems to automatically and accurately define the TCP in six dimensions. Concurrently, establishing a fixed world coordinate system in the work cell, referenced to the part or fixture, ensures that programmed paths execute in the correct real-world location every time. This integration of arm, tool, and workspace calibration is what transforms a general-purpose servo arm robot into a dedicated precision machine.

Implementing a Continuous Calibration Protocol

Recognizing that parameters can drift due to wear, temperature, or mechanical loads, a static calibration is insufficient for long-term precision. An advanced approach institutes a protocol for periodic verification and compensation. This may involve scheduled re-calibration using fixed targets within the cell or the integration of in-line sensors that provide continual feedback. For a polishing robot, a laser profilometer could periodically scan a test piece to measure results and trigger a recalibration if tolerances shift. This shift from a one-time setup to a managed calibration lifecycle maintains system accuracy over thousands of cycles, protecting product quality and reducing scrap.

The pursuit of ultimate repeatability and accuracy is a continuous process rooted in sophisticated calibration. It requires addressing errors from the robot's internal kinematics to its external tooling and operational environment. For manufacturers utilizing a servo arm robot in roles demanding exactitude, such as operating as a polishing robot, investing in these advanced calibration methodologies is not merely a technical step; it is an operational necessity. At JAKA, we engineer our systems to support this rigorous approach, providing the stability and precision needed to turn complex robotic programs into consistently flawless execution.