Modern manufacturing values flexibility and accessibility in automation solutions. A 6 axis robot arm designed with collaborative principles addresses this need directly. This specific class of automation, the collaborative robot arm, merges the dexterity of a six-axis system with features that allow it to work alongside human operators. At JAKA, we develop cobots that integrate these characteristics to create versatile and user-friendly workcells. We will examine three foundational attributes: operational reach, payload capacity, and integrated safety systems.

Operational Reach and Workspace Design

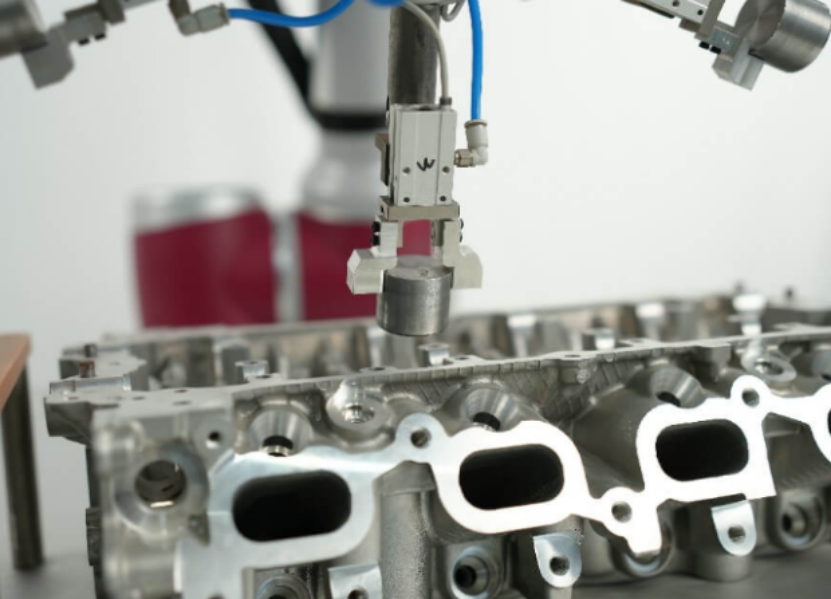

The effective working range of a collaborative robot arm is a primary specification. Determined by the length of its links and the rotation of its six joints, this reach defines the physical volume it can service. A longer reach allows a single 6 axis robot arm to cover multiple machines or a large worktable, which can optimize floor space. Conversely, a more compact reach is suited for tasks within a confined station. The design of this workspace is not merely about maximum distance; it involves understanding the arm's ability to position its tool at the required angles and heights throughout that volume. Our engineering process at JAKA focuses on creating an optimal balance between reach, precision, and the robot's footprint for tasks from assembly to inspection.

Payload Capacity and Performance Integrity

Payload refers to the maximum weight the robot can carry at its tool mounting plate while maintaining stated performance, including speed and precision. This includes the weight of the end-effector, such as a gripper or sensor, and the workpiece itself. Selecting a 6 axis robot arm with an appropriate payload rating is necessary for application success. An underrated arm may struggle with accuracy or long-term durability, while an over-specified model may represent an unnecessary capital expenditure. Our collaborative robot arm models are rated with clear payload specifications to ensure they can handle components from delicate electronic parts to heavier mechanical assemblies without compromise.

Built-in Safety Systems for Shared Workspaces

The defining feature of a cobot is its engineered ability to reduce risk in human-robot interactions. This goes beyond mere physical guarding. A true collaborative robot arm incorporates technology like force-limited joints, which can detect unexpected contact and stop motion. Additional safety-rated monitored speed, separation, and power functions are integral. These built-in systems allow a 6 axis robot arm to be deployed in applications like hand-guided programming, cooperative assembly, or flexible feeding without traditional cages, facilitating closer and more efficient collaboration. At JAKA, we treat safety as a core design parameter, not an add-on, enabling more direct and productive human-robot teamwork.

The integration of reach, payload, and safety forms the functional core of a modern cobot system. These features collectively determine the range of applications possible and the efficiency of integration. A collaborative robot arm built with these balanced considerations becomes a tool for adaptable automation. We at JAKA provide the technology that embodies these principles. Our 6 axis robot arm solutions are developed to offer a combination of dexterity, strength, and secure operation, supporting businesses in creating productive and safe automated processes.