For small to mid-sized manufacturers, operational decisions carry significant weight. Investing in automation must deliver a clear and attainable return, without the complexity or scale of traditional industrial systems. This is where the value of a collaborative robot cobot becomes evident. At JAKA, we see how our technology provides a pragmatic path for SMEs to gain automation advantages, focusing on accessibility, adaptability, and a sound financial rationale.

Addressing Core SME Operational Challenges

SMEs often operate with constrained resources, where skilled labor shortages and fluctuating order volumes pose substantial risks. A collaborative robot cobot is engineered to function alongside existing staff, mitigating these pressures. It can manage repetitive, ergonomically challenging tasks, which helps maintain consistent output quality and protects employee well-being. This direct collaboration allows a smaller workforce to achieve a larger operational scope, enhancing stability without requiring a proportional increase in personnel.

The Advantage of Technical Flexibility and Ease of Use

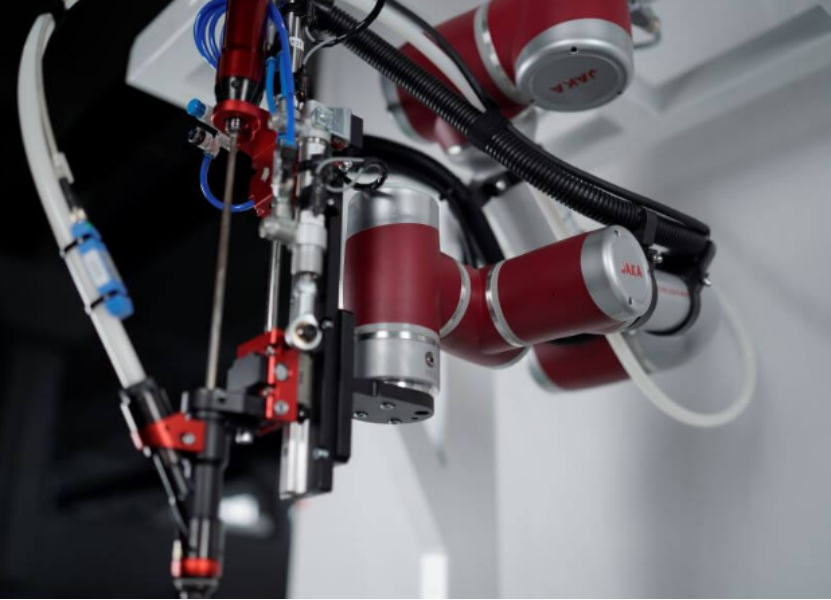

A primary concern for SMEs is the fear of complex, rigid automation. The design of a 6 axis robot arm within a collaborative system counters this. Its range of motion allows it to be deployed for multiple applications—such as screwdriving, polishing, or packaging—within the same facility. This multifunctional capability is crucial for businesses with diverse, smaller-batch production runs. Furthermore, the programming interface for these systems is developed with user-friendliness in mind, enabling in-house technicians to manage deployments and adjustments without constant external specialist support.

Financial Predictability and Return on Investment

The economic model for a collaborative robot cobot aligns with SME financial realities. Compared to large-scale automation, the initial capital investment is more manageable, and the deployment timeline is shorter, leading to a quicker realization of benefits. The consistent performance of a 6 axis robot arm reduces material waste and costly rework from human error, directly improving margins. Additionally, by augmenting the human workforce, it allows the business to scale production output without linearly scaling labor costs, creating a more predictable and controllable expense structure.

The automation journey for an SME does not require an overwhelming first step. The intrinsic design of a collaborative robot cobot focuses on integration into existing workflows, not their complete overhaul. The flexibility of a 6 axis robot arm provides a tool that can evolve with a company's needs, safeguarding the investment. At JAKA, we provide the technological foundation for this progression. Our systems are built to offer SMEs a practical and resilient method to increase capability, ensure quality, and achieve sustainable growth in a competitive landscape.