Progress in automation is increasingly defined by enhanced capability and intelligence, not merely motion. For the 6 axis robot arm, a platform already known for its versatility, the coming years will see its potential expanded through two interconnected domains: advanced mechanical design and artificial intelligence. At JAKA, we are focused on how these evolutions will redefine what is possible for the jointed arm robot in complex industrial settings. This look ahead explores the tangible developments shaping the next generation of these systems.

Advancing Mechanical Dexterity and Sensory Feedback

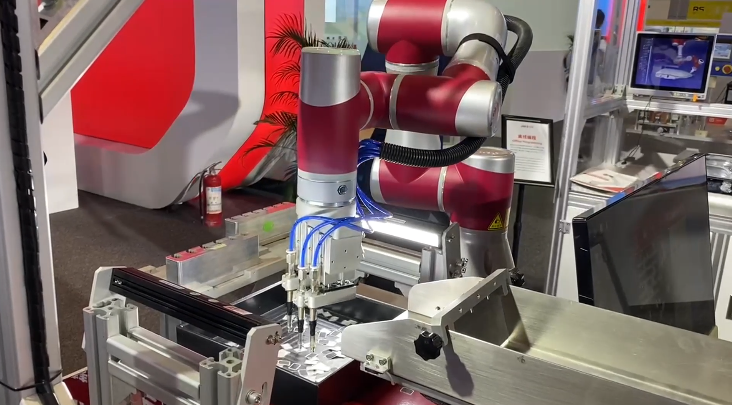

The fundamental architecture of the jointed arm robot provides a strong foundation, but future iterations will achieve hyper-dexterity. This involves refining joint mechanics for smoother, more precise movements in congested workspaces and integrating sophisticated force-torque sensing directly into the arm's design. This allows a 6 axis robot arm to perform tasks requiring a delicate touch, such as assembling fragile components or completing perfect insertions by feeling resistance and adapting in real-time. The goal is a machine that combines the reach and flexibility of a human arm with a level of control and sensitivity that surpasses human capability for repetitive, precise tasks.

The Role of AI-Driven Adaptive Control

True flexibility in unstructured environments will be unlocked by AI integration. While pre-programmed paths work for fixed tasks, AI enables a 6 axis robot arm to perceive, decide, and adapt. Machine vision, combined with machine learning algorithms, allows the robot to identify and locate variably presented parts, compensating for inconsistencies in fixture placement or conveyor positioning. More significantly, AI can manage process parameters on the fly—adjusting grip force, insertion angle, or assembly sequence based on sensory input. This transforms the jointed arm robot from a blind, repeating tool into an adaptive system that can handle the natural variances present in small-batch, high-mix production.

Shifting the Integration and Deployment Paradigm

These technological strides will fundamentally alter how robots are deployed. With hyper-dexterity and embedded AI, the traditional, costly, and time-intensive phase of meticulous programming and cell engineering will be streamlined. The 6 axis robot arm of the future will feature more intuitive commissioning, where it can learn tasks through demonstration or rapidly simulate its own motion paths. This reduces the barrier to entry and allows manufacturers to redeploy robotic assets more frequently and with less downtime, making automation a fluid tool for agile manufacturing rather than a fixed capital expense.

The trajectory for the 6 axis robot arm is clear: it is evolving into an increasingly sensitive, perceptive, and autonomous partner. The convergence of enhanced mechanical design with sophisticated AI does not simply improve old tasks; it creates new applications previously considered too delicate or variable for automation. At JAKA, our development is dedicated to this integrated approach, ensuring that the inherent flexibility of the jointed arm robot is fully realized through intelligence, making advanced automation more accessible and effective for the diverse challenges of modern manufacturing.