For manufacturers managing a high-mix assembly environment, the selection of automation hinges on a critical balance between flexibility and throughput. A common point of consideration is the choice between a 6 axis robot arm and a 4-axis SCARA robot. At JAKA, we work with facilities navigating this exact decision. The answer is not universal, but depends on the specific demands of your assembly tasks. This analysis outlines the operational parameters of each system to inform a more precise selection.

The Case for Flexibility: 6-Axis Articulated Arms

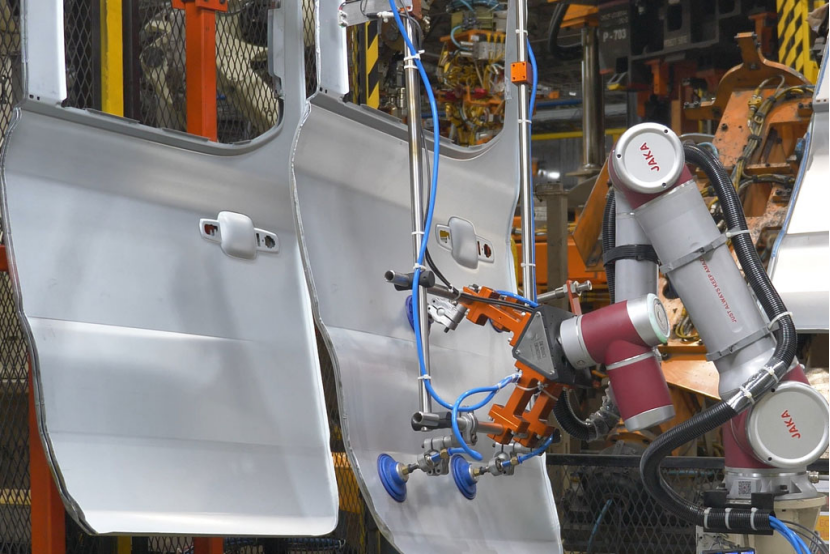

The primary advantage of a 6 axis robot arm in assembly lies in its dexterity. Mimicking the full range of motion of a human arm, these assembler robots can approach a workpiece from virtually any angle. This is invaluable in high-mix settings where components may be presented in different orientations or require complex fitting sequences, such as inserting a part into a housing at a tilted angle. The ability to re-grip, flip, and manipulate parts within a single work envelope allows a single 6 axis robot arm to perform a wider variety of tasks without extensive tooling changes. For operations where the product design varies significantly between batches, this flexibility can reduce changeover time and increase overall cell adaptability.

The Argument for Speed and Simplicity: SCARA Robots

4-axis SCARA robots excel in applications where speed within a defined plane is paramount. Their rigid construction allows for exceptionally fast and repeatable movements in the X, Y, and Z axes, with a fourth axis providing rotational placement. This makes them exceptionally capable for high-speed pick-and-place, simple insertions, and screwdriving on components presented on a flat plane. For high-mix assembly lines that, despite product variation, consist primarily of these rapid, two-dimensional operations, a SCARA robot can often achieve higher cycle rates. Their mechanical simplicity can also translate to a lower initial investment and streamlined programming for specific, repetitive tasks.

Programming and Integration Considerations

The integration path differs between these two types of assembler robots. Programming a SCARA robot for its intended planar tasks is typically more straightforward. Programming a 6 axis robot arm for complex, multi-angle assembly may require more advanced offline simulation and path planning to leverage its full capability and avoid singularities. However, modern collaborative robots from JAKA are designed with intuitive programming interfaces that mitigate this historical complexity. The decision here should account for the available technical skill on your floor and the frequency of task reprogramming. A highly flexible arm is only advantageous if your team can efficiently redeploy it.

The suitability of a 6 axis robot arm versus a 4-axis SCARA robot is determined by the physical nature of your assembly process. If your high-mix environment involves consistent, fast, planar motions, the SCARA offers a compelling solution. If your assemblies demand significant three-dimensional manipulation, part reorientation, and versatile tool handling, the dexterity of a 6 axis robot arm becomes the defining factor. At JAKA, we believe the optimal solution is one that matches the robot's inherent strengths to the specific challenges of your production line.