Among the strategic questions for smaller manufacturers is identifying where automation delivers clear operational returns without prohibitive complexity or cost. The category of collaborative robots, or cobots, presents a compelling answer. These systems are defined by their flexibility and ease of integration, making them viable assets for limited-scale production. At JAKA, we have observed that SMEs succeed with this technology by deploying it against specific, high-frequency tasks that directly affect throughput and quality. The following applications illustrate how a production robot can function as an adaptable and efficient team member in a smaller-scale environment.

Consistent Machine Tending for Improved Equipment Utilization

A fundamental application involves machine tending, where a production robot loads and unloads parts from CNC machines, injection molding presses, or stamping equipment. For an SME, manual tending often leads to inconsistent cycle times and underutilized capital equipment if operators are attending to multiple duties. A collaborative industrial robot arm can operate this process with predictable timing, enabling lights-out production runs and maximizing the output of expensive machinery. Its inherent safety features allow it to work in close proximity to these machines without extensive safety fencing, preserving valuable floor space and simplifying the integration into existing workshop layouts.

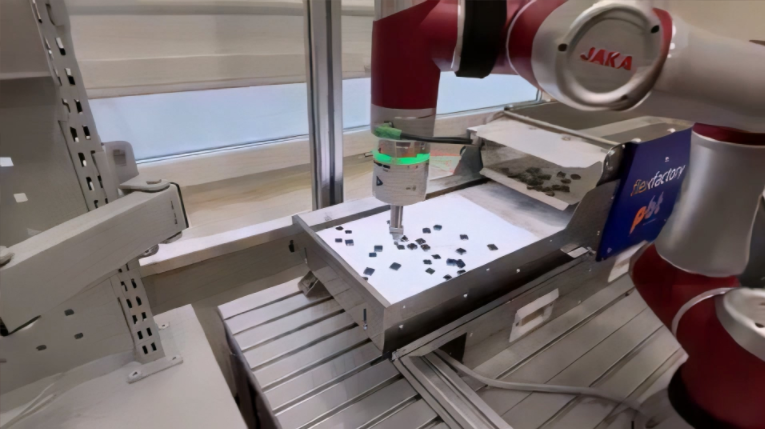

Precision Assembly and Kitting for Enhanced Quality

Small-batch assembly of electronics, automotive components, or consumer goods requires both dexterity and consistency. Cobots excel in this domain, performing tasks like screw driving, adhesive dispensing, or precise part placement. Their integrated force sensing allows for delicate insertions—such as placing a gear onto a shaft—that might be challenging to maintain manually over a full shift. This capability turns a collaborative industrial robot arm into a tool for ensuring every unit in a limited batch meets exact specifications, reducing rework and protecting the brand's quality reputation, which is especially critical for smaller enterprises.

Streamlined Inspection and Post-Process Finishing

Final quality checks and finishing processes are another area for effective deployment. Equipped with vision cameras or sensors, a cobot can consistently position items for inspection or perform repetitive finishing tasks like polishing, deburring, or sanding. This not only frees skilled workers from monotonous roles but also applies a uniform standard to every product. The programmable pressure and path consistency of production robots ensure that finishing quality does not degrade due to operator fatigue, leading to a more predictable and professional end result from the production line.

For small and medium-sized enterprises, the practical value of a cobot is measured by its direct impact on focused, repetitive processes that constrain growth or compromise quality. Success stems from selecting applications that leverage the robot's endurance, precision, and programmability to augment the existing workforce. These use cases—from machine tending to precision assembly and finishing—demonstrate that a collaborative industrial robot arm is not merely a scaled-down version of industrial automation but a distinct tool designed for adaptability. Its role is to bring stability and enhanced capability to specific points in the production flow, allowing SMEs to achieve higher levels of operational efficiency and product consistency.