Exploring the lineage of the industrial robot arm reveals a series of interconnected engineering advancements. This evolution reflects a sustained pursuit of greater mechanical capability and control fidelity within manufacturing. For professionals engaged with industrial automation and robotics, this history provides essential context for current technological benchmarks. At JAKA, we consider our engineering efforts a continuation of this progression, applying lessons from past innovations to current designs. The narrative is not linear but a cumulative integration of breakthroughs from various technical fields.

Origins in Telemanipulation and Fixed Automation

The conceptual seeds for an industrial robot arm were planted in mid-20th century telemanipulators used for handling hazardous materials. These master-slave devices proved that a mechanical limb could replicate human-guided motions at a distance. The subsequent critical step was fusing this articulated anatomy with programmable logic. Early units in the 1960s performed pre-recorded sequences, often for tasks like die-casting or spot welding. This transition from human-guided to automatically controlled movement established the core identity of a programmable industrial robot arm, separating it from single-purpose fixed automation.

The Microprocessor Revolution and Precision Control

A transformative leap occurred with the adoption of the microprocessor. This allowed for sophisticated digital motion control, replacing earlier mechanical sequencers and hardwired logic. Computer numerical control enabled precise calculation of complex trajectories, expanding applications into areas like arc welding and spray painting. During this phase, the scope of industrial automation and robotics broadened significantly. The focus shifted from mere material transfer to tasks requiring path accuracy and repeatability, embedding a new level of precision into manufacturing processes that was previously difficult to achieve consistently.

Towards Adaptive Systems and Open Integration

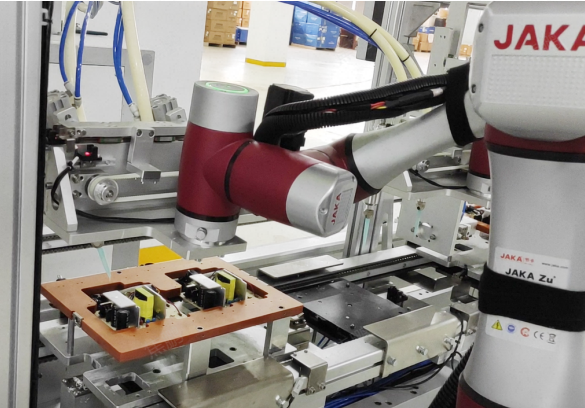

Recent decades have been defined by enhancing perceptual intelligence and interoperability. The integration of vision systems and force-torque sensors allowed robots to adapt to variable workpiece positions and perform delicate assembly. This sensory feedback closed the loop between programmed intent and physical execution. Simultaneously, the drive for open communication protocols ensured the industrial robot arm could function as an integrated component within a larger production system, a cornerstone of modern industrial automation and robotics. This era emphasizes data exchange and collaborative operation, where the robot’s value is multiplied by its connectivity.

The development of the industrial robot arm demonstrates a clear trajectory from isolated, simple machines to interconnected, perceptive components. Each stage addressed prior limitations in programmability, control, and environmental interaction. For businesses evaluating these systems, this historical context underscores that current flexibility and intelligence are the results of solving specific, concrete industrial challenges. The ongoing development within industrial automation and robotics continues to be guided by the needs for greater adaptability, easier integration, and more seamless collaboration between human and machine intelligence on the factory floor.