Ensuring a secure working environment around automated equipment is a fundamental responsibility. The integration of an industrial robot arm into a production line introduces powerful capabilities that require correspondingly rigorous safety practices. We believe that safety is not a single feature but a continuous process built on protocol, knowledge, and technology. A methodical approach to operating an arm robot industrial system protects personnel, safeguards capital investment, and maintains uninterrupted production flow.

Conducting a Comprehensive Risk Assessment

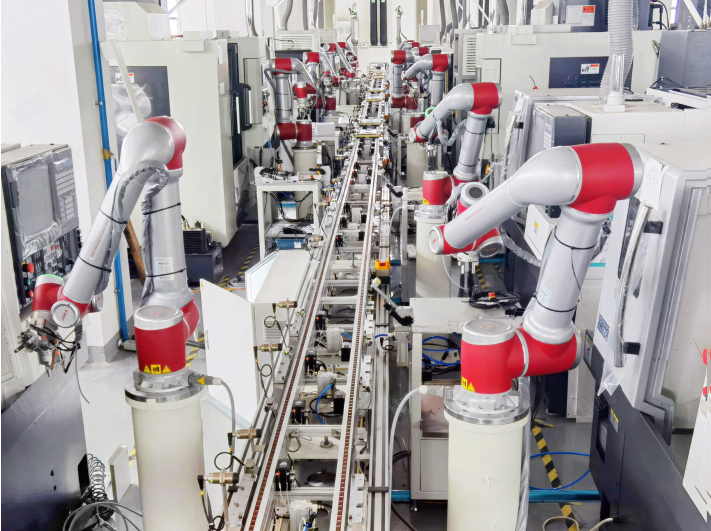

Before initiating any operational cycle, a thorough site-specific risk assessment is indispensable. This process involves identifying all potential hazards, including pinch points, trajectory paths, and peripheral equipment interactions. For any industrial robot arm, the assessment must define clear safeguarding perimeters, which may incorporate physical barriers, light curtains, or laser scanners. Establishing these zones mitigates the risk of unexpected human entry into the machine’s active workspace. This foundational step informs all subsequent safety protocols and hardware configurations.

Implementing Structured Training and Clear Procedures

Operational safety is directly linked to human understanding. Personnel interacting with the system must receive structured training that covers both routine procedures and emergency responses. This includes safely programming, starting, and pausing the arm robot industrial, as well as executing a controlled shutdown. Training must emphasize the importance of following lockout-tagout (LOTO) procedures during maintenance to ensure the system is de-energized. Consistent adherence to documented workflows reduces variability and the potential for procedural errors that could lead to unsafe conditions.

Maintaining System Integrity and Utilizing Built-in Features

The physical and functional upkeep of the robotic cell is a critical safety pillar. A regular maintenance schedule for mechanical components, such as checking joint integrity and cable condition, helps prevent failures. Simultaneously, operators should fully utilize the industrial robot arm’s inherent safety functions. Modern systems often include software-based features like adjustable speed limits, programmable soft axis limits, and collision detection algorithms. Activating and correctly configuring these built-in electronic safeguards provides an essential layer of active protection that complements physical barriers.

A holistic safety strategy combines pre-implementation planning, continuous education, and proactive technical oversight. The effective and secure use of an arm robot industrial depends on respecting its power while systematically managing risks through defined practices. Our development philosophy at JAKA integrates this principle by designing systems with accessible safety interfaces and robust construction. Committing to these operational disciplines fosters a culture of safety that is essential for sustainable and productive automation in any industrial setting.