Achieving faster changeovers is a direct path to improved flexibility and responsiveness in manufacturing. A primary tool for this task is the cobot robot, designed for adaptability in dynamic production environments. The implementation strategy, however, determines whether this potential is fully realized. At JAKA, we see effective deployment for quick changeovers as a system-wide plan, addressing physical mobility, intuitive reprogramming, and peripheral integration. This approach moves beyond installing a single industrial robot arm to designing a process that can be reconfigured with minimal downtime and technical burden.

Designing for Physical Mobility and Access

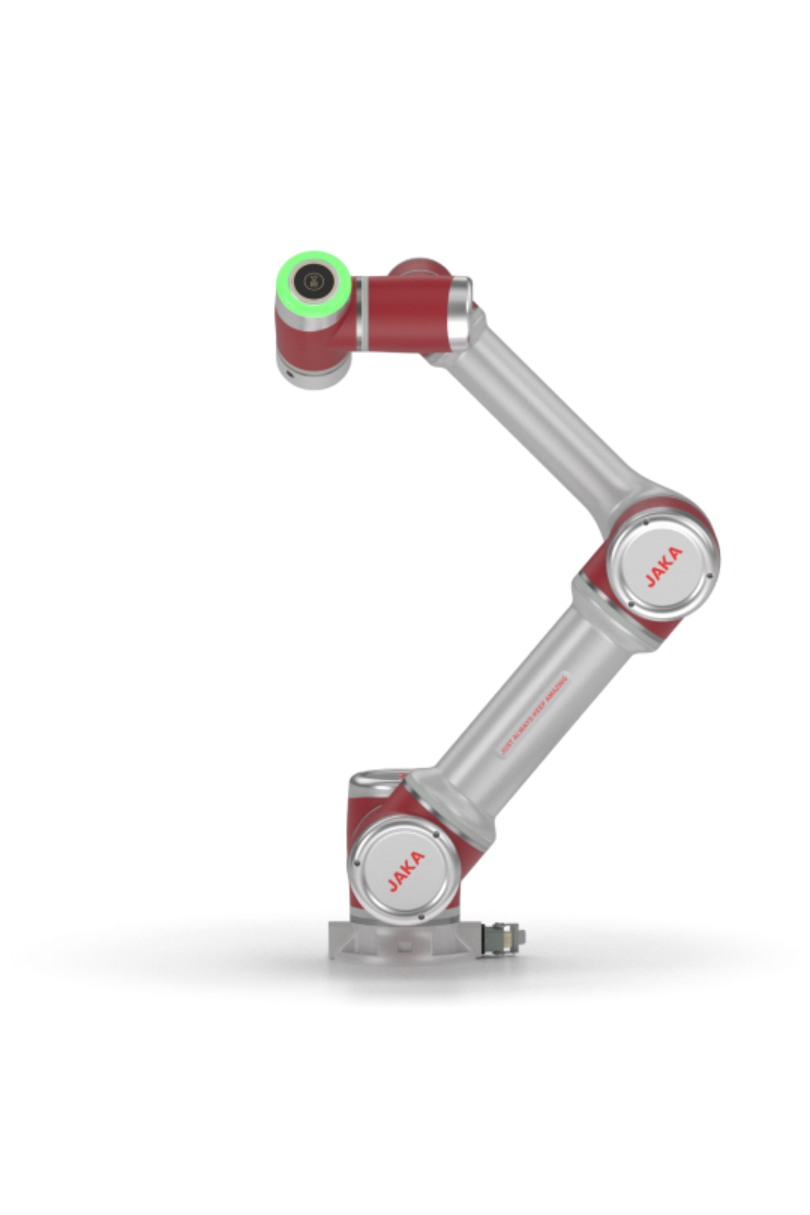

The foundation for rapid redeployment is hardware designed for movement. A traditional industrial robot arm is often installed on a fixed, heavy base, making relocation time-consuming and resource-intensive. Effective implementation starts with selecting a cobot robot built for portability. This includes a lightweight arm structure and an equally compact, separable controller. Units can then be mounted on mobile carts or lightweight frames, enabling operators to wheel the system between stations or lines as demand shifts. This physical flexibility transforms the automation from a fixed asset into a shared resource that can be applied where it is most needed, directly supporting agile production scheduling.

Utilizing Intuitive Programming for Task Switching

When a process changes, reprogramming cannot become a bottleneck. The software interface used for the industrial robot arm is therefore critical. Systems reliant on complex code create dependence on specialist programmers. Effective implementation leverages intuitive methods like hand-guided teaching or graphical drag-and-drop interfaces. These tools allow line technicians, who understand the process best, to quickly demonstrate new paths or adjust parameters. By reducing the reprogramming barrier, the time required to switch from assembling one product variant to another shrinks significantly. This operational simplicity is a core reason businesses adopt a cobot robot for high-mix, low-volume scenarios.

Integrating Quick-Change Tooling and Peripherals

The arm itself is only one component; the end-effector and associated peripherals must be equally adaptable. Effective implementation standardizes connection points, such as pneumatic and electrical interfaces on the tool flange, to support a library of quick-change grippers or tools. Furthermore, the workcell should be designed with easily repositionable fixtures and sensors. This holistic setup allows the core industrial robot arm to remain in place while operators rapidly swap physical tooling and update the corresponding program module. The cell becomes a reconfigurable platform, where changeover is a systematic, repeatable procedure rather than a custom engineering task.

Implementing for swift changeovers is a deliberate design philosophy. It requires selecting hardware that is physically mobile, software that is operationally simple, and creating a peripheral ecosystem built for quick disconnection and reconnection. When these elements align, the result is a production asset that provides not just automation, but automation that adapts at the pace of the business. This capability allows companies to respond to shifting orders and shorter product lifecycles efficiently. The value of the system is measured not only in cycle time but in the remarkable reduction of the time it spends idle between different tasks.