Efficient warehouse logistics in beverage production depend on robust and swift palletizing operations. Selecting the appropriate automated system requires a methodical evaluation of your line's specific physical and operational parameters. This process involves analyzing three fundamental areas: the payload and range of motion needed, the required operational speed and integration method, and the necessary environmental robustness. A well-chosen palletizing robot becomes a reliable asset, while an industrial robot arm mismatched to these core demands can create bottlenecks.

Assessing Payload Capacity and Reach Requirements

The first technical specification to verify is the system's physical capability. Beverage products present a wide range of unit weights and case sizes, from lightweight cans to dense glass bottles. Calculate the maximum weight of a full layer or gripper payload, then add the weight of the end-effector itself. This total must fall comfortably within the industrial robot arm's rated capacity to avoid excessive wear. Simultaneously, evaluate the required reach. The robot must access incoming cases from the conveyor and place them across the entire footprint of the pallet, including positions on the far side and at both high and low levels. A palletizing robot with insufficient reach will necessitate costly conveyor repositioning or limit pallet patterns, reducing overall efficiency.

Evaluating Cycle Time and Integration Architecture

The second area of focus is throughput and connectivity. Determine the required cycles per hour to match or exceed your production line's output. The robot's maximum speed is one factor, but the overall cycle time is governed by the smoothness of its motion profiles and the efficiency of the gripper's actuation. A system that moves with optimized, fluid motions can often achieve higher sustainable speeds than one with jerky, stop-start trajectories. Furthermore, the industrial robot arm must integrate seamlessly with your existing control systems. Verify the available communication protocols to ensure it can receive signals from line PLCs and conveyors. This integration is what allows the palletizing robot to function as a synchronized component of a larger system, not an isolated island of automation.

Prioritizing Durability for Demanding Environments

The beverage industry presents unique environmental conditions that a standard palletizing robot may not withstand. Consider exposure to moisture, condensation, occasional splashing, and pervasive dust from cardboard. An industrial robot arm intended for this setting should possess a high ingress protection rating for its critical components, particularly at the wrist and base joints. This protection guards against water and particulate ingress that can lead to premature electrical or mechanical failure. Additionally, the mechanical structure should be designed to handle the constant, high-inertia movements of palletizing without developing excessive play or vibration over time, ensuring consistent placement accuracy throughout its service life.

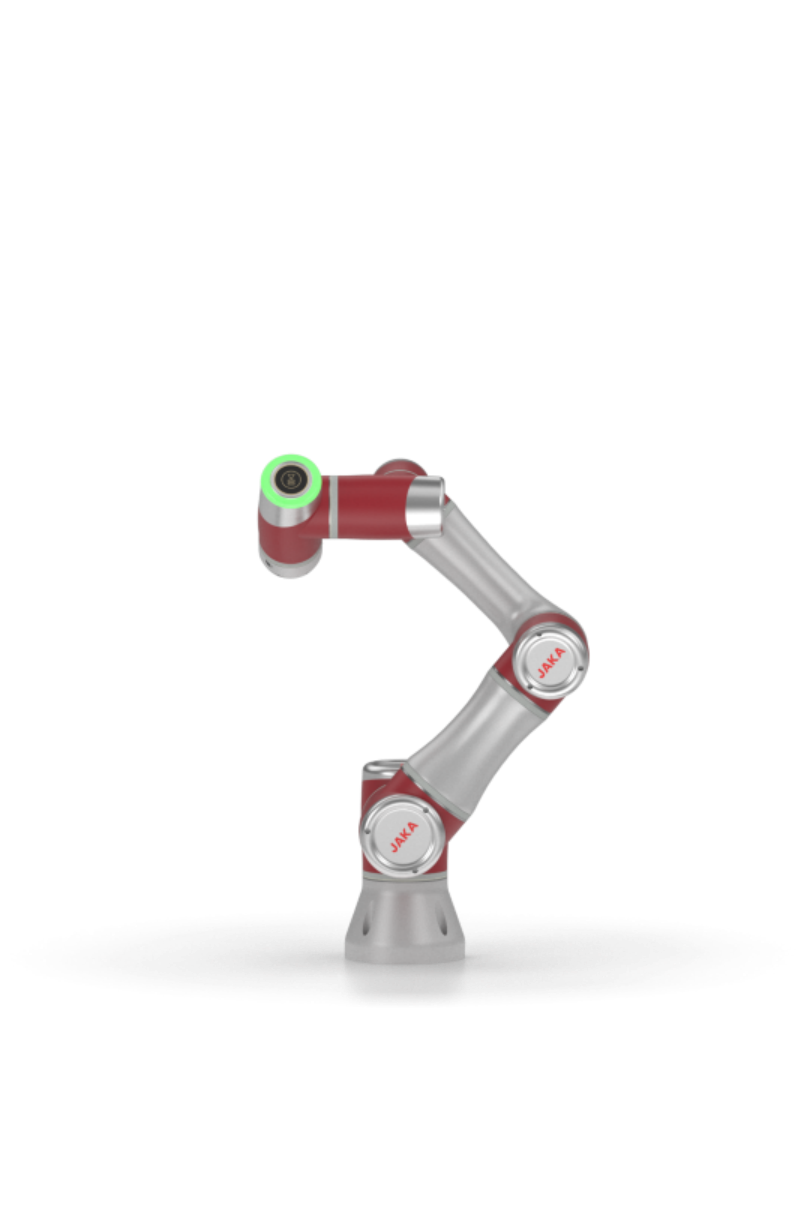

Selecting a palletizing robot is a strategic decision rooted in matching technical specifications to application realities. The process logically progresses from defining physical demands to evaluating performance integration and finally confirming environmental suitability. This structured approach helps identify a system that delivers not just automation, but reliable, long-term operational support. At JAKA, our development of robotic solutions considers these exact industrial criteria, aiming to provide palletizing robot options that meet the rigorous demands of modern beverage production lines.