Many businesses encounter a common hurdle when considering automation: the perception that it requires extensive expertise, major infrastructure changes, and significant capital. JAKA robotics operates on a different principle. We function as a cobot company dedicated to simplifying this transition. Our core mission is to provide adaptable tools that bridge the gap between manual processes and full automation. The operation of our systems centers on intuitive design, integrated technology, and a focus on safe collaboration, aiming to make robotic assistance a practical reality for workshops and factories of various scales.

A Product Philosophy Centered on Accessible Deployment

The operational approach of our systems begins with reducing physical and technical barriers. We design our cobot platforms, such as the lightweight Zu and Mini series, with an emphasis on low weight and compact form factors. This deliberate design choice allows a single worker to mount the arm on a workbench, a mobile cart, or even an AGV without needing heavy lifting equipment. The complementary controller is equally streamlined. This physical ease of deployment is matched by a software environment built for users without robotics programming backgrounds. Features like drag-and-drop teaching and graphical app interfaces translate an operator's physical guidance into precise, repeatable digital paths. The initial interaction with a JAKA Robotics system is intended to be direct and uncomplicated, minimizing setup time and specialized training.

Core Technologies Enabling Adaptive and Precise Motion

The internal functionality that allows our systems to perform valuable work rests on several integrated technological pillars. For tasks demanding sensitivity and fine control, such as precision assembly or finishing, our S series incorporates advanced force sensing. This technology allows the arm to perceive and respond to contact forces, enabling applications like compliant insertion, surface following, and gentle handling. Across our product lines, high-fidelity encoders and adaptive servo algorithms work in a closed loop to ensure movement accuracy and path repeatability. Furthermore, built-in intelligence, such as singularity management and vibration suppression algorithms, ensures motions are not only precise but also smooth and predictable. This combination of responsive sensing, accurate control, and smart motion planning is what transforms a simple articulated arm into a capable collaborative robot.

A Structured Ecosystem for Diverse Industrial Demands

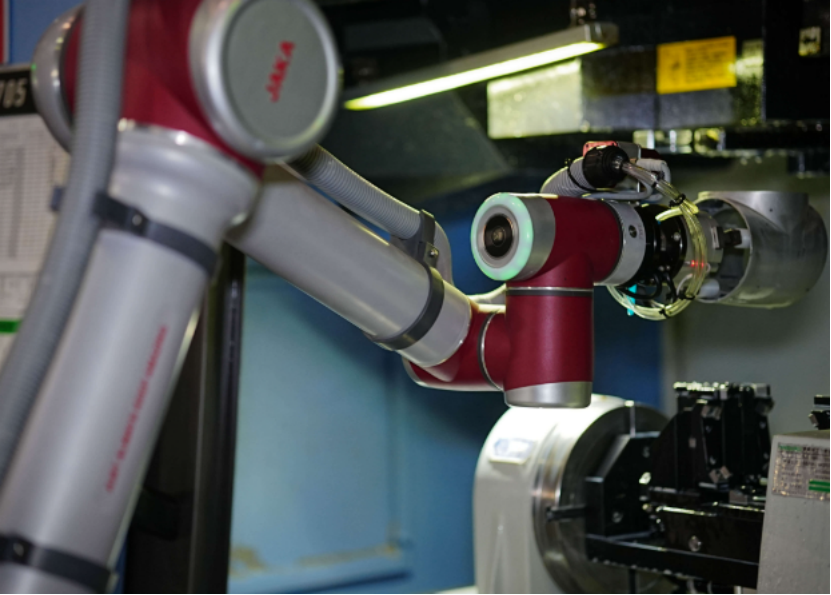

Understanding that no single solution fits all applications, our approach as a cobot company is to offer a coordinated ecosystem. This range addresses distinct environmental and performance needs. The All-in-one series, with vision hardware and software directly integrated, is engineered for applications requiring immediate visual guidance like pick-and-place from bins. For challenging environments, the Pro series is built with high ingress protection ratings and enhanced reliability for settings where dust, oil, or coolant is present. From the cost-effective, desktop-scale Mini to the high-performance Pro, each model in the JAKA Robotics portfolio shares the foundational principles of ease of use and collaborative safety, but is optimized to provide a specific set of capabilities for different challenges on the factory floor.

The essence of our work at JAKA Robotics is to demystify automation through practical engineering. Our systems function by being physically straightforward to deploy, intellectually accessible to program, and technologically equipped to handle a spectrum of precise and adaptive tasks. As a dedicated cobot company, we provide not just isolated machines, but a scalable framework of collaborative automation, aiming to turn robotic potential into a simple, operational reality for businesses ready to enhance their productivity.