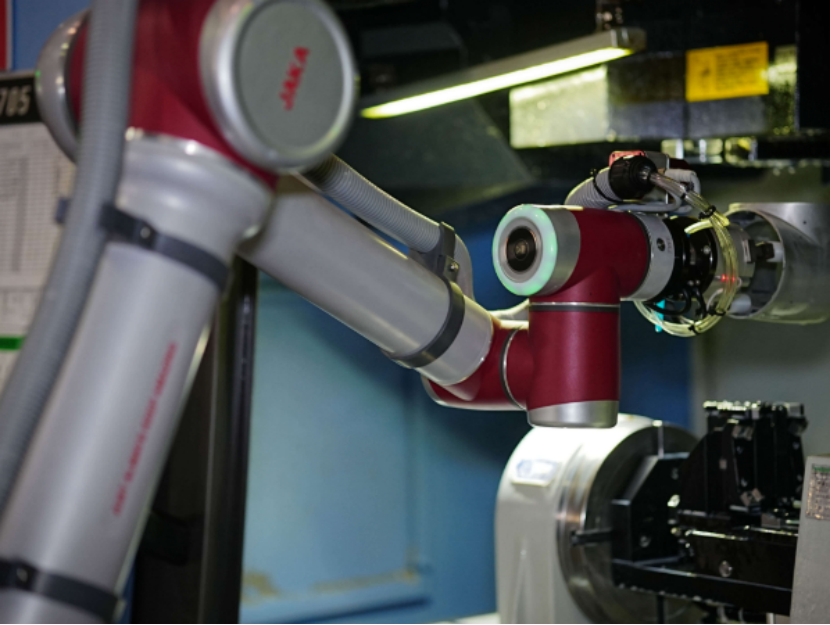

When integrating automation, safety transitions from a secondary consideration to a foundational design principle. For any business implementing industrial robotic automation, navigating the landscape of safety standards is a critical step that dictates system design, operational protocols, and legal adherence. This framework exists not to limit functionality, but to ensure that productivity and personnel protection are aligned. At JAKA, we approach these standards as essential parameters that guide our development from initial concept to final deployment, ensuring our systems meet rigorous international benchmarks.

Conducting a Comprehensive Risk Assessment

The initial phase of any project involving industrial robotic automation must be a thorough risk assessment. This systematic process identifies potential hazards associated with the robot's tasks, its workspace, and all human interaction points. It evaluates the severity and likelihood of harm, forming the basis for all subsequent safety measures. This assessment is not a one-time event but a recurring analysis, especially when the application or cell layout changes. The output directly informs the selection of protective measures, whether they involve hardware safeguards, software limits, or procedural controls, ensuring a validated safe work environment.

Implementing Collaborative Operation Safeguards

For a collaborative robot designed to share space with humans, safety is engineered directly into its functionality. Standards define specific collaborative operation modes, such as power and force limiting or hand guiding, which require built-in technological safeguards. These include features like force feedback sensors, passive rounded designs, and software that limits speed and torque upon contact. Our development incorporates multiple layers of these active and passive protections. This integrated approach allows a collaborative robot to operate effectively alongside staff without traditional hard guarding, but always within the calculated safety parameters established during the risk assessment.

Integrating with Machine Safety Systems

A robot is seldom an island; it is part of a larger cell. Therefore, safety compliance extends to the entire workcell through the concept of a machine safety system. This involves the integration of peripheral safety devices—like light curtains, safety mats, and interlocks on access doors—with the robot's safety controller. This creates a unified safety circuit where a breach at any point brings the system to a safe state. Effective industrial robotic automation requires this seamless communication between all components, ensuring the robot and its connected equipment act as a single, compliant entity under relevant machinery directives.

Adherence to safety standards in industrial robotic automation is a multifaceted discipline that balances technical innovation with unwavering protective protocols. It begins with a rigorous assessment of potential risks and continues through the selection of appropriate collaborative technologies and the integration of a unified safety system. This structured approach does not hinder operational efficiency; rather, it establishes the reliable and predictable foundation necessary for sustainable automation. By treating these standards as integral to the design process, businesses can deploy advanced solutions like a collaborative robot with confidence, knowing that performance and safety are built upon the same robust framework.