In industrial settings, a shift is occurring toward machinery designed to work alongside human teams. These machines, known as collaborative robots or cobots, represent a distinct category of automation. Unlike traditional industrial robots that operate behind safety cages, a collaborative robot is built for direct interaction within shared workspaces. At JAKA, we view the core principle of this technology as adaptive and safe cooperation, creating hybrid workflows where human skill and robotic consistency combine effectively. This integration aims to augment productivity and flexibility on the factory floor.

Core Functionality and Design Philosophy

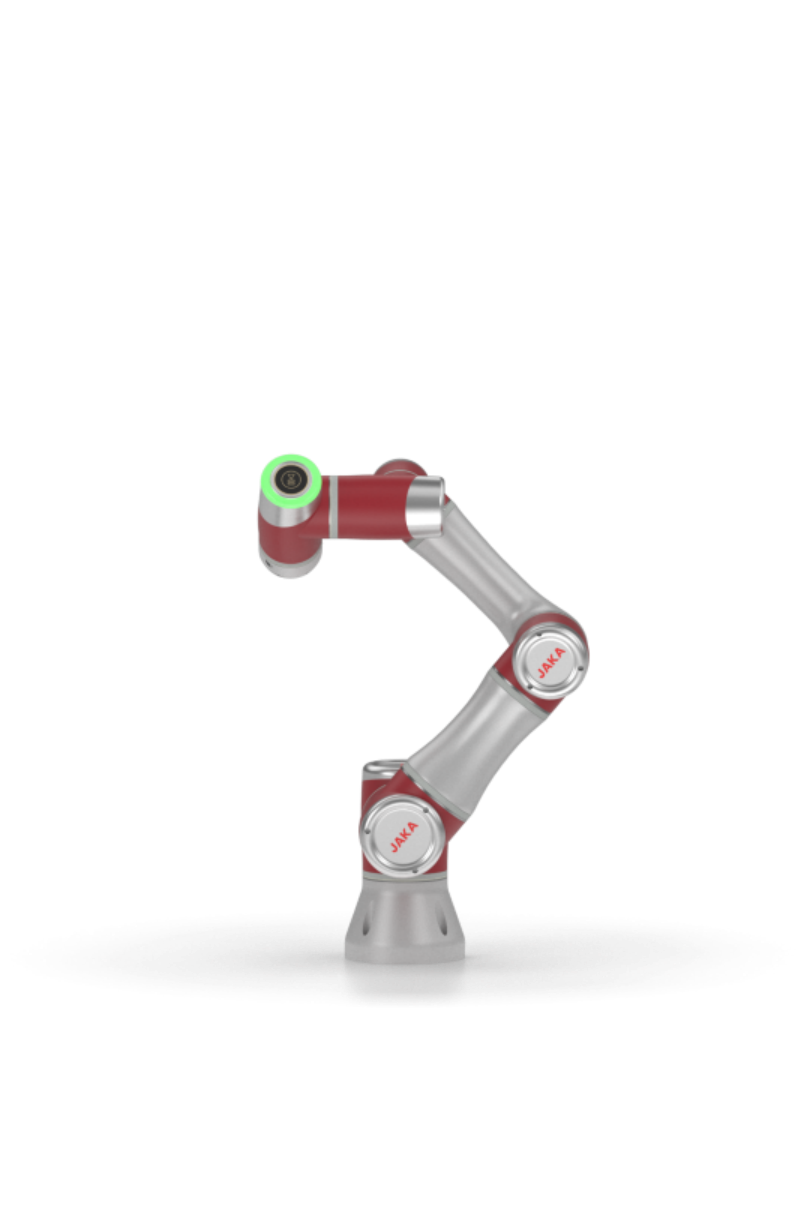

The defining characteristic of a collaborative robot is its inherent focus on safe coexistence with people. This is achieved not through isolation but through integrated safety features. These include force-limited joints, rounded physical designs, and sensors that detect unexpected contact. For instance, our development incorporates algorithms for collision protection and jitter suppression. This design philosophy means a cobot can be deployed closer to human operators without extensive safety fencing, allowing for more compact workcell designs and easier reassignment of tasks. The objective is direct partnership, where each agent performs functions suited to their strengths.

Enabling Accessibility Through Simplified Interaction

A significant barrier to traditional automation has been operational complexity. A primary advancement of the collaborative robot model is the reduction of this barrier. Many cobots, including our own, utilize intuitive methods like hand-guided teaching and graphical programming interfaces. This approach allows workers without specialized robotics training to program and manage the equipment. By transforming setup from a code-based task to a more physical, guided process, these systems become versatile tools that line operators can directly adapt to new tasks, supporting agile manufacturing responses.

Integration and Application Flexibility

The value of a cobot is realized through its integration into existing processes. Modern units are engineered for connectivity, supporting various communication protocols to interface with vision systems, tooling, and factory networks. This allows a collaborative robot to act as a responsive node within a larger system. For example, a single JAKA cobot might perform screw-driving on one line and later be redeployed for precise assembly or quality inspection, guided by different end-effectors and software packages. This flexibility makes the technology suitable for high-mix, variable-volume production where changeovers are frequent.

The concept of the collaborative robot centers on creating a synergistic work environment. It merges the repeatability and endurance of machines with the cognitive flexibility and problem-solving ability of human workers. For businesses, this means deploying automation that is adaptable, easier to implement, and capable of improving ergonomics and productivity. The technology continues to develop, focusing on more sophisticated environmental perception and decision-making to make human-robot collaboration even more seamless and effective.