In modern industry, we frequently talk about efficiency, speed, and cost, metrics that build powerful production empires. But behind these numbers lies a silent, heavy challenge centered around people. Many workers still endure extreme heat, oil, freezing winds, or toxic corrosion every day.

We hope to shift the burden of these harsh environments from humans to robots. By challenging our robots to be more stable, durable, and protective, we want to help humans work safer and live better.

High-Temperature Environment

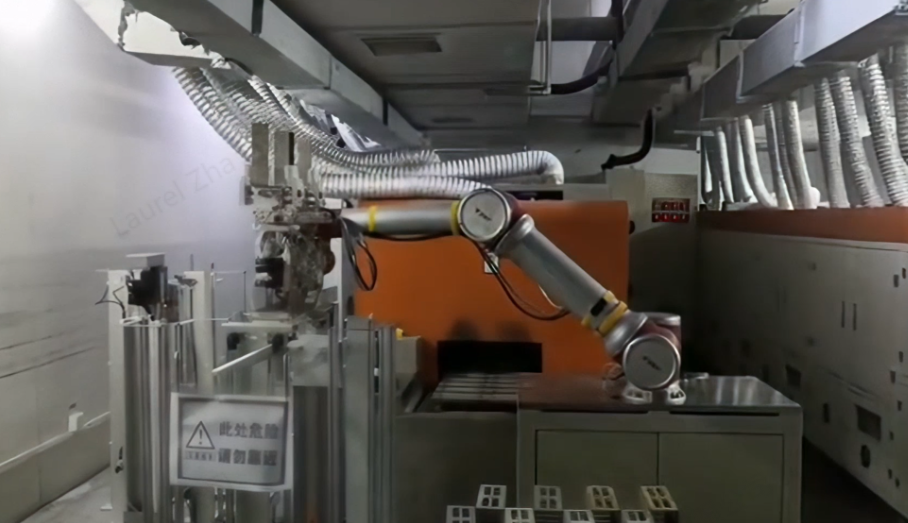

In the LED chip baking process, oven temperatures soar up to 300°C, causing the chips themselves to reach extremely high temperatures. Manually loading the trays presents a significant safety risk, making it a task that few workers are willing to take on. Companies also face difficulties with recruitment and retention.

JAKA optimized its robot's mechanical structure with a specialized integrated heat dissipation design to prevent overheating. JAKA Zu series also boasts an impressive 80,000-hour Mean Time Between Failures (MTBF). Now, one JAKA Zu12 is handling two workstations. Its highly stable performance ensures both rapid tray transfers and long-term, reliable operation.

Dusty Environment

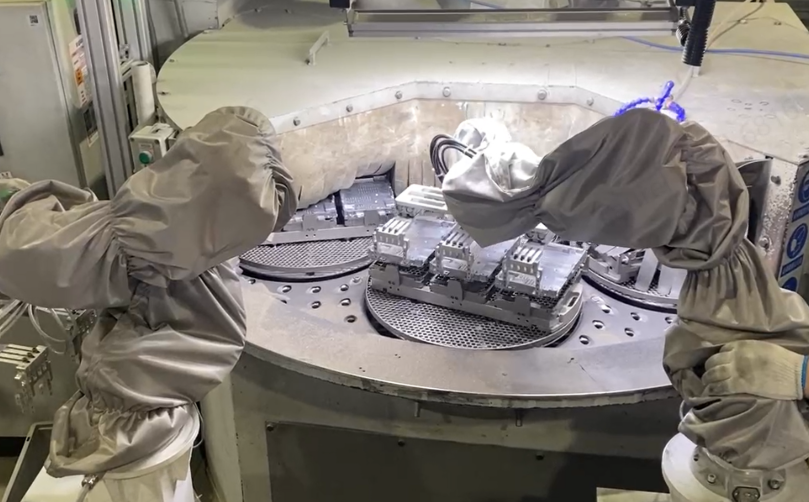

A workshop sandblasting hard drive casings previously required six workers per shift. The shop was excessively loud and dusty, which not only hurt hearing and respiratory systems but also caused eye irritation from metallic dust. The client needed robots to take over. However, for a robot, the abundant, electrically conductive metallic dust created by the sandblasting process meant a high risk of short circuits.

After working with the JAKA team, the client installed eight JAKA Zu12 cobots. JAKA cobots features a highly integrated joint design with reinforced sealing from the core to the casing, effectively blocking conductive dust. The line now requires only one employee working safely away from the blast zone. Five workers can be transferred to higher-value roles.

For similarly challenging conditions, JAKA later in 2022 launched the JAKA Pro High-Protection Series, which offers further upgrades in IP rating, sealing, and environmental adaptability, providing more robust options for similar jobs.

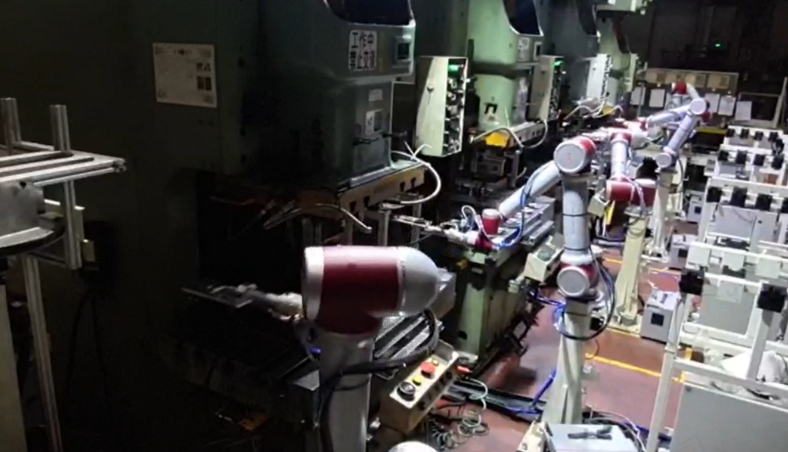

Oily and Greasy Environment

Machining uses large amounts of cutting fluids and emulsions, and raw workpieces often have oil residue. These liquids can splash onto the robot surface and potentially seep into internal parts like joints and motors. Some older production lines are heavily soiled with oil and grease, requiring high durability and reliability from the robot.

JAKA Pro Series holds the industry's highest IP68 protection rating. They can easily handle industrial scenarios involving heavy oil and excessive cutting fluids, and have been adopted by many automotive companies for their critical production lines.

Explosion Risk

An energy station in Xinjiang deployed its first smart refueling robot, integrating JAKA Pro16. The robot operates autonomously 24/7. Drivers can order, refuel, pay, and get a receipt entirely from their car via an app.

Notably, this station is located in Northwest China with a desert climate. The station faces high winds, heavy dust, and sand, extreme day-night temperature swings, and winter lows of -10°C, testing the robot's sealing, weather resistance, heat dissipation, and low-temperature startup capabilities. Furthermore, the energy station itself is classified as a typical dust explosion hazard location. JAKA Pro16 comes with a high-protection design, excellent sealing and robust environmental resistance, allowing it to be modified to meet the required explosion-proof standards.

Corrosion Risk

Loading 70% concentrated sulfuric acid is a high-risk operation. Opening tanker lids exposes workers to corrosive fumes and liquids that cause irreversible harm. This task often requires them to work at dangerous heights, compounding the safety risk.

JAKA Pro12 integrates a 3D vision camera and a force control sensor to accurately locate and tighten/untighten the tank port. The robot syncs coordinates directly with the acid loading arm for a fully automated process. Introducing the robot not only ensures personnel safety but also prevents production accidents caused by inconsistent manual operation.

Outdoor Environment

As high-speed rail networks expand, the number of traction substations is increasing, leading to a heavier inspection workload. Traditional manual inspections are labor-intensive and inefficient, with the collected data often failing to be integrated into management systems accurately and in a timely manner.

When the rail network extends into remote areas—such as high-altitude regions with low oxygen, high-cold permafrost, or the Gobi desert—staff face significant safety risks while inspecting in adverse weather conditions like strong winds, fog, ice, snow, hail, and thunderstorms.

In this context, a JAKA Zu7 robot, mounted on an AGV and equipped with a vision system, can create an autonomous patrol system. This system provides continuous surveillance and disaster warnings across equipment, environmental factors, and security. It allows management to remotely assess conditions, drastically improving inspection efficiency while keeping personnel safe from harm.

Across those demanding environments, reliability—whether in the standard series or the high-protection series—is just as critical as intelligence. This unwavering focus sets JAKA apart in a competitive market. By tackling these challenges, we empower our robots to become high-value partners in humans' works and lives.