In some demanding applications, accuracy demands more than just position. Since its launch in 2024, the JAKA S Series has leveraged integrated, high-performance force control to deliver a new experience for scenarios where sensitivity is key.

What does the "S" in JAKA S stand for?

Structured: Integrated design with no exposed wiring, saving I/O interfaces and maintaining a clean, compact profile.

Smooth: 35% reduction in dragging effort and automatic zero-drift sensor calibration for fluid motion.

Strong: IP65 rating and an industry-leading 15x overload capacity (max 3000N/300Nm).

Stable: Pioneered singularity avoidance provides early warnings and automatic arm stabilization.

Simple: "One-click" start with easy "Point" and "Free" buttons on the arm for quick force control.

The "S" can also refer to "Scenario" Focusing.

Ⅰ Assembly

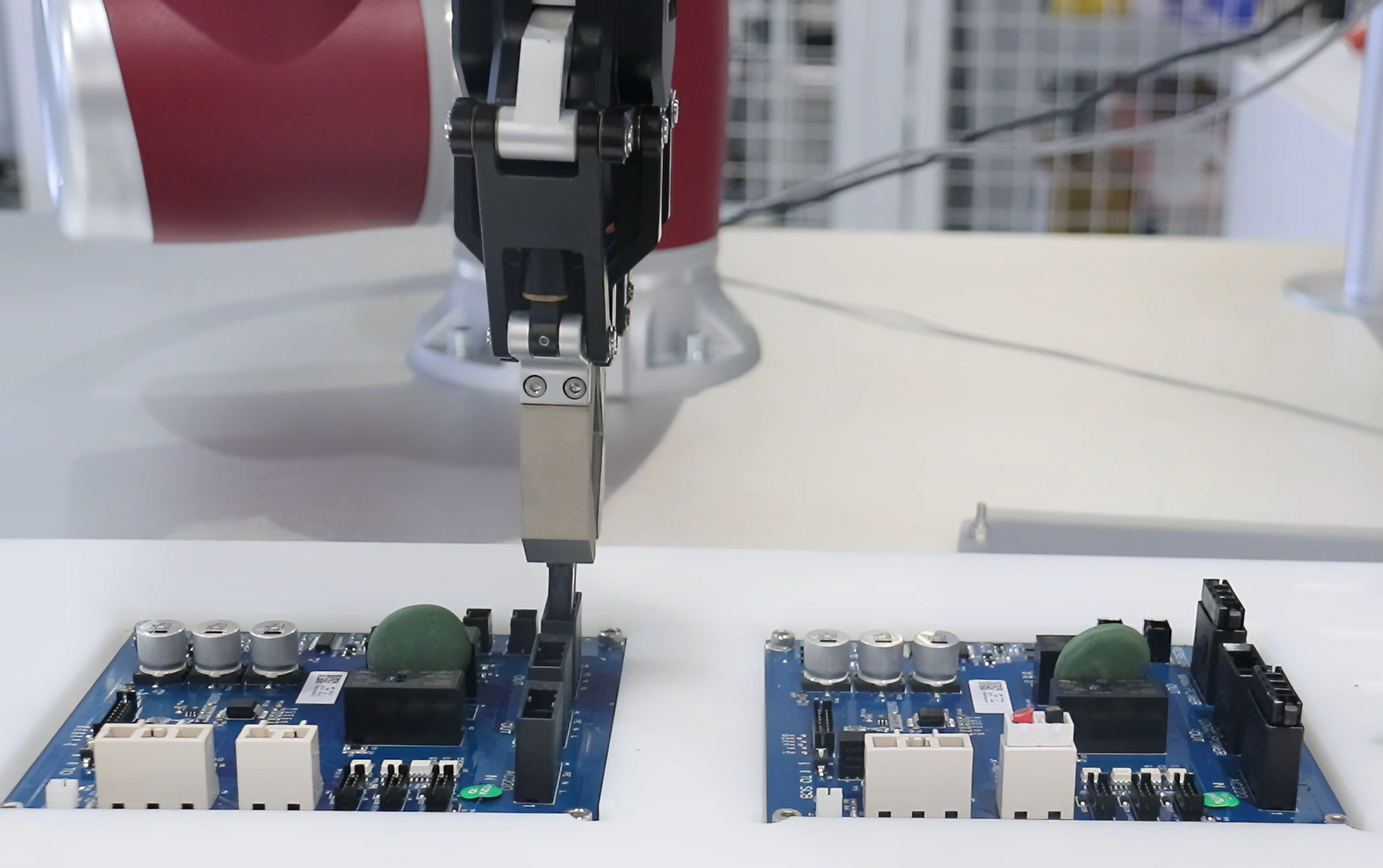

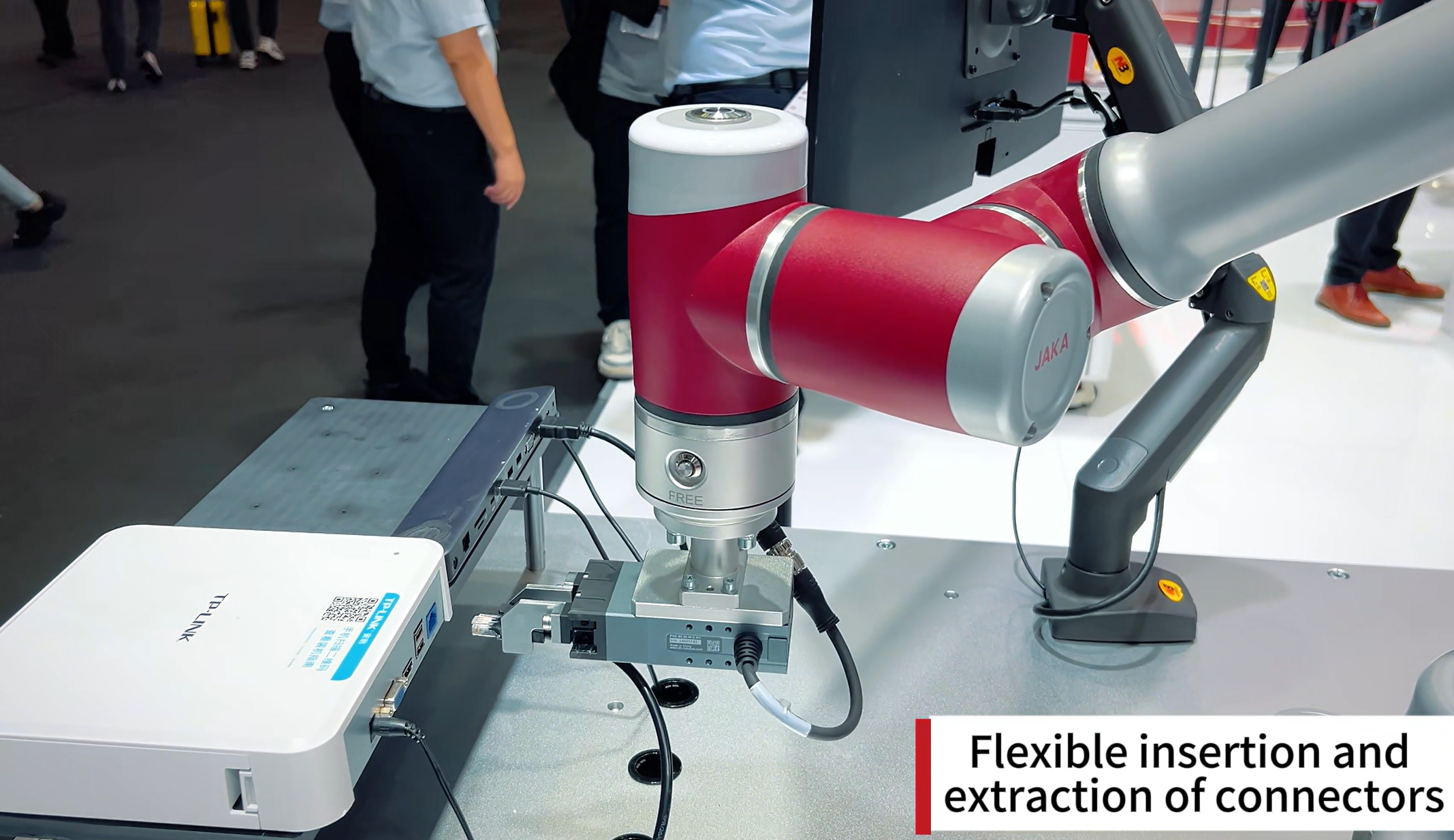

In delicate tasks like Peg-in-Hole or connecting electronic components, parts often have slight tolerance deviations. If a traditional, rigid robot encounters even a slight misalignment, it often forces the fit, risking costly damage or jamming.

For plugging electronic components—such as USBs, power cables, or PCB connectors—the required insertion force must be 'just right': tight enough for a secure connection, but not so aggressive as to bend pins or scratch the casing.

JAKA S is engineered for this nuance, boasting a 1% F.S. overall accuracy and 0.05% F.S sensor resolution. In these fine operations, the robot accurately and sensitively detects the slightest resistance during contact, alignment, or minor sticking. It gently adjusts its angle and position until the part slides smoothly into place.

The process of refueling or charging an vehicle is mechanically similar to industrial assembly. As electric vehicles become common and autonomous driving matures, the role of the charging robot becomes increasingly vital.

Since a vehicle is rarely parked in the exact same spot, even after a vision system locates the port, precise insertion requires the cobot to have tactile feedback to make continuous micro-adjustments. This is where the JAKA S excels. Additionally, with its IP65 rating, the JAKA S ensures stable operation in dynamic outdoor environments.

Ⅱ Medical Assistance

In the medical field, human arms—though sensitive—are prone to fatigue and minor tremors during prolonged, high-pressure operations (such as multi-hour surgeries). Human hands struggle to maintain consistent force and ultra-high precision over extended periods. As a solution, some hospitals use robots to provide continuous assistance to doctors throughout the procedure.

In dental implantology, for example, the dental implant surgical robot integrated with JAKA S is already in use. This system tracks patient movement in real time to ensure precise implant positioning and guides the surgical tool, assisting surgeons in placing implants accurately according to pre-operative plans.

Given that medical surgical spaces are often small and visually restrictive, traditional large robots can be impractical. Medical professionals need quick, intuitive equipment that doesn't require lengthy programming sessions. JAKA S’s compact design and user-friendly interface enable it to operate efficiently in confined spaces, providing precise guidance in areas that are difficult for the doctor to see.

Ⅲ Lightweight Cinema Robot

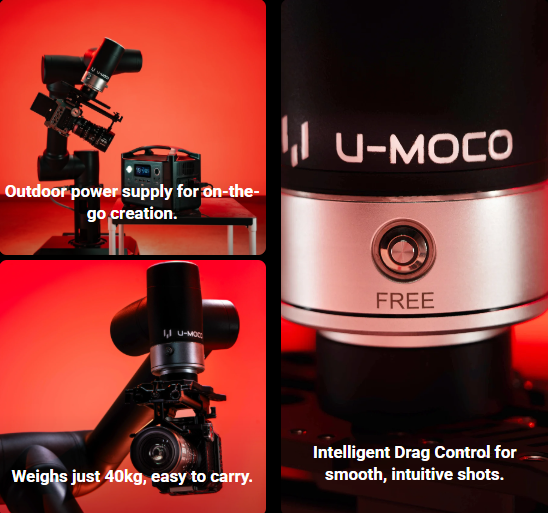

As short videos and live streams drive the new "light industry" of filmmaking, the demands on cinematic robotic arms have changed. The nature of short video and live commerce requires flexibility and speed. Filmmakers need a camera robot that offers movie-grade fluid motion and convenient operation, remains stable when carrying professional camera gear, and is lightweight enough for rapid deployment indoors and outdoors.

This necessity is why one of our partners, U-MOCO, adopted the JAKA S Series to create their lightweight cinematic robot, the U-MOCO AIR.

JAKA S reduces dragging effort by 35%, resolves shaking and drifting issues, and supports whole-body dragging. With ±0.03 repeatability, it ensures perfectly tracked shots at speeds of up to 3m/s. The entire U-MOCO AIR system, with a 1.3-meter reach, weighs only 40kg, making it easy to deploy in various locations—unlike traditional, heavy cinema robots that are difficult to transport and set up. Its modular graphical control and smooth drag-and-teach mode allow photographers to use the system with just a few hours of training, without the need to learn complex robot programming or external setup.

The applications of the JAKA S extend far beyond those listed. JAKA S can solve much more unique challenges, such as massage, curved surface polishing, keyboard button testing, force-controlled ironing of automotive seats, and the glue wiping of earphones.

To meet these growing and evolving demands, JAKA remains focused on advancing robotic perception, decision-making, and interaction technologies. Countless scenarios urgently require robots like JAKA S to enable smarter and more flexible automation.