The controller is the electronic 'brain' behind the cobot's every move. It might not always grab the headlines, but when you're excited about what the cobot can achieve—its accuracy, stability, or the economic benefits from automation—you want that brain making sure it reaches its full potential, without holding things back. That's where the JAKA CAB V3 steps in.

JAKA CAB V3 supports most JAKA Cobots, except for JAKA Mini Series and JAKA MAX Series; Software adaptation and optimization will be completed by August. Users can choose the JAKA CAB V3 when purchasing a new cobot, or purchase a JAKA CAB V3 separately to work with owned cobots.

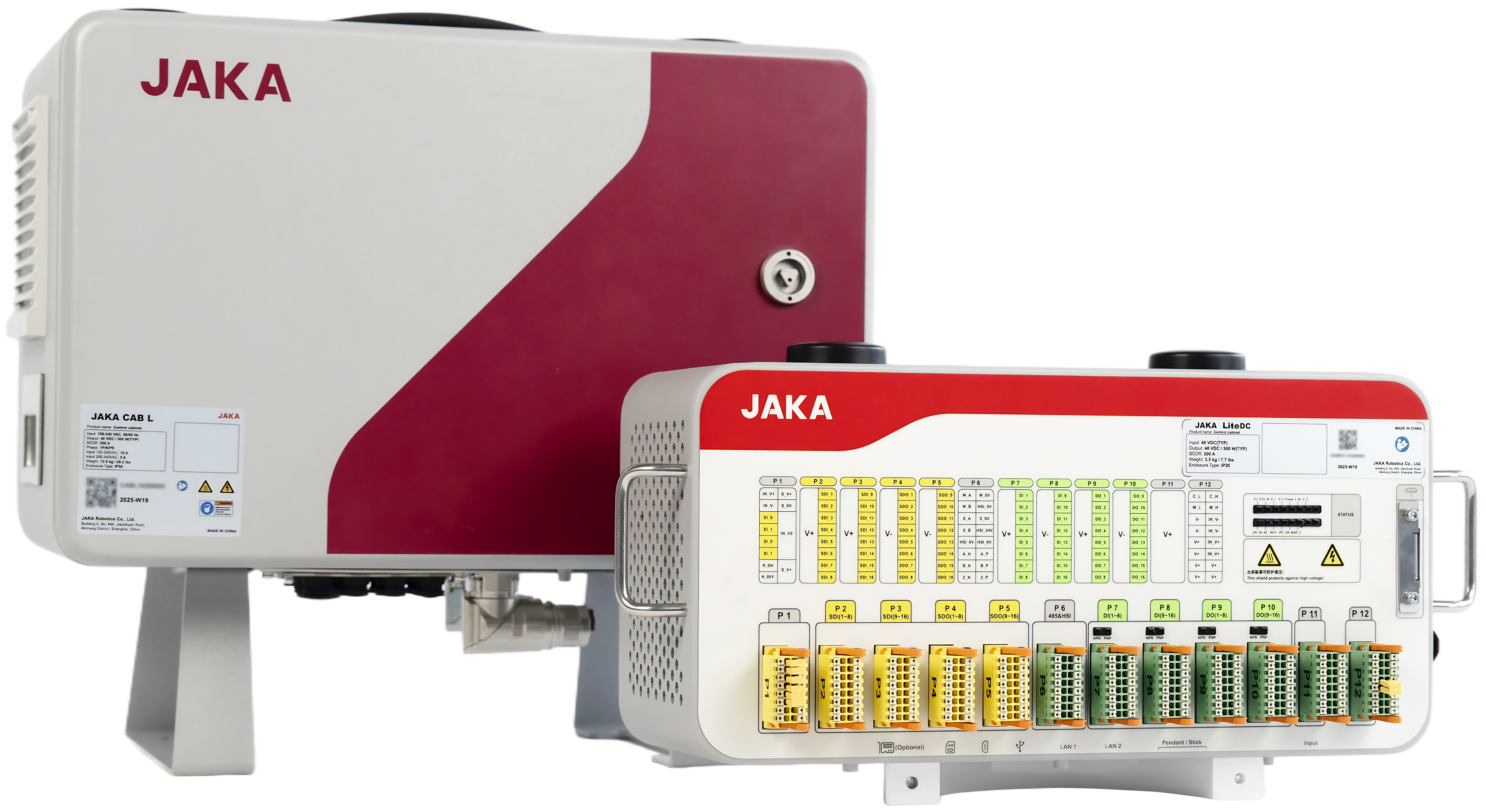

ⅠFlexible Deployment Options

① Available in IP54-rated standard and Lite variants.

② The Lite version supports AC or DC input and weighs as little as 3.4 kg, making it ideal for mobile or space-constrained applications.

① Standard Versions: Foot mounting, Hand mounting, Rear mounting

② Lite Versions: Rail mounting, bracket mounting

Ideal for:

✔ Suspended installation in automotive welding lines.

✔ Wall-embedded configurations in cleanroom environments.

✔ Integration with AGVs for mobile automation.

✔ Deployment in confined spaces such as narrow aisles or elevated platforms.

✔ Operation under demanding conditions, including high heat and cleanroom standards.

Ⅱ Adaptability & Performance

Durable Construction

① The standard version features IP54 protection and operates reliably in ambient temperatures from 0°C to 50°C.

② Support for –20°C ~ 60°C environments is currently under development.

Quiet Operation & EMI Immunity

① Equipped with dual-fan cooling, the system normally operates at 45dB.

② Enhanced EMC/EMI resistance ensures stable performance in sensitive environments such as medical facilities and inspection systems.

Precision Motion Control

An upgraded jitter suppression algorithm enables smoother motion, shorter cycle times, reduced vibrations, and higher positioning accuracy, with automatic parameter tuning.

Multi-Axis Coordination

Supports up to 12 axes (6 robot axes + 6 external axes), with real-time, synchronized control between the JAKA cobot and external motion devices such as linear rails and rotary positioners.

Ⅲ Seamless Connectivity & Scalable Architecture

Native support for PROFINET (Slave), EtherCAT (Master), and Ethernet/IP (Slave) enables smooth integration with various automation systems.

Predefined expansion ports allow for optional module integration (e.g., PROFINET Master), enabling the cobot to function as a PLC or master controller when needed.

Offers 16× DI, 16× DO, 16× CI, and 16× CO—twice the I/O capacity of the previous JAKA CAB V2.1.

Supports configurable sink/source inputs (NPN/PNP) to ensure compatibility with global electrical standards, including Japanese–European hybrid production lines.

Default safety I/O supports response times of under 0.01 seconds, ensuring rapid signal processing and system responsiveness.